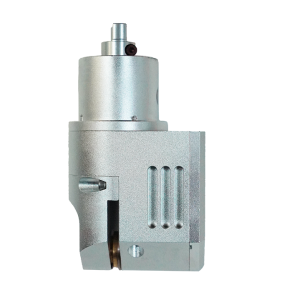

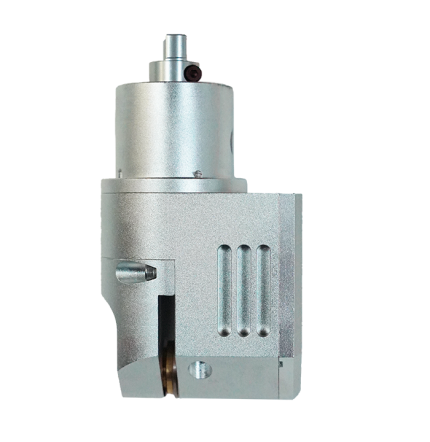

The important product – servo circular knife, can process various textiles such as sheep wool, UV cloth, carbon fiber, banners, flag cloth, blackout cloth, etc.

The basic principle of circular knife is to cut the material by driving the blade to rotate at high speed through the motor. According to the needs, different types of cutter heads can be selected and matched with different blades to realize the processing of different materials.

Component Description

Air inlet: internal cooling gas inlet

Fixed block: connects to the tool holder support rod

Lock: used to lock the tool handle

Tool handle: round tool body

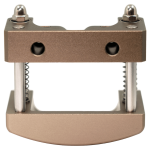

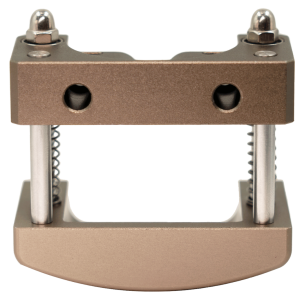

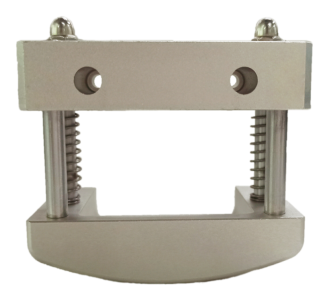

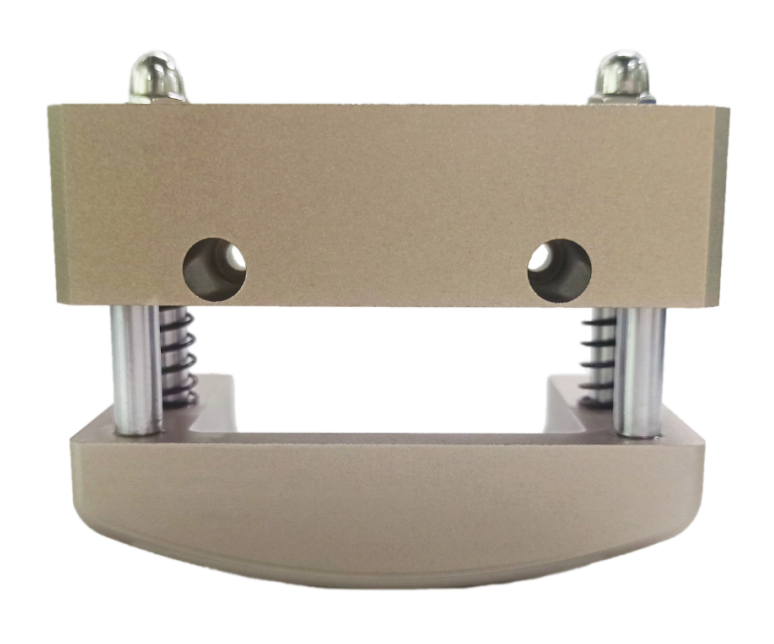

Round tool head: clamps the blade

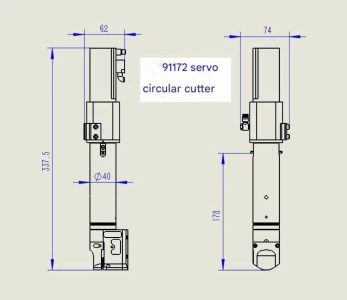

Installation Dimensions

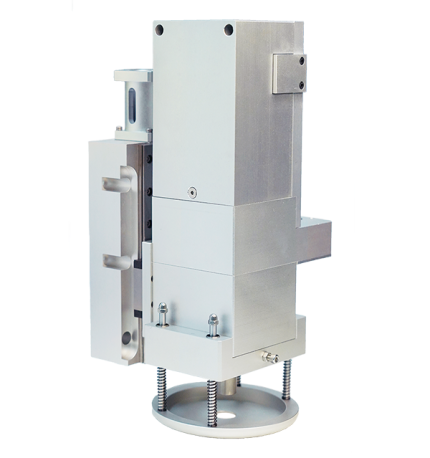

Installation Diagram

The schematic diagram of servo circular knife installation is as follows:

Instructions for use and debugging

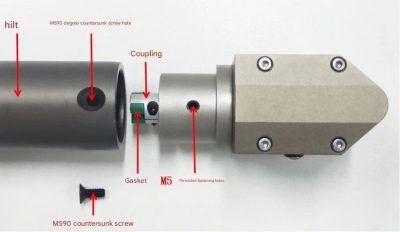

(1) Cutting head installation

Check if there is a gasket on the tool head coupling (the gasket may also be at the connection in the middle of the tool handle).

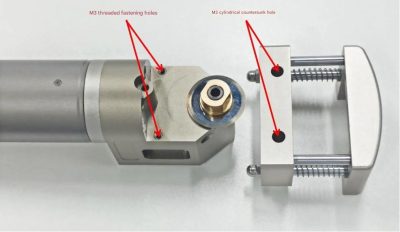

Align the M5 threaded fastening hole of the tool head with the M5-90 countersunk screw hole and insert it (pay attention to the groove at the connection when inserting, and connect it accordingly).

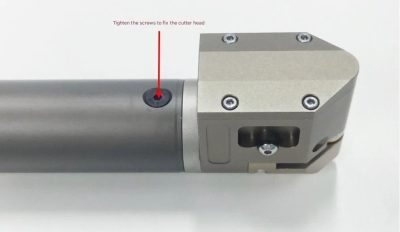

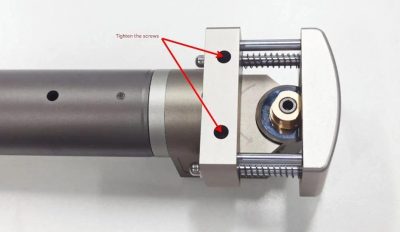

Finally, put in the M5-90 countersunk screw and tighten the screw with a hexagonal wrench to fix the tool head.

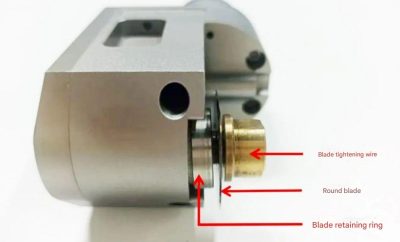

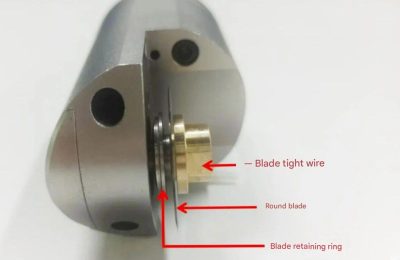

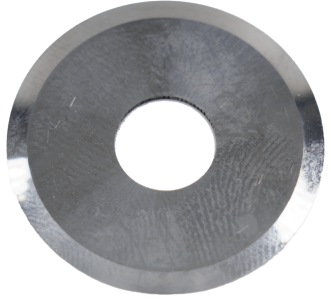

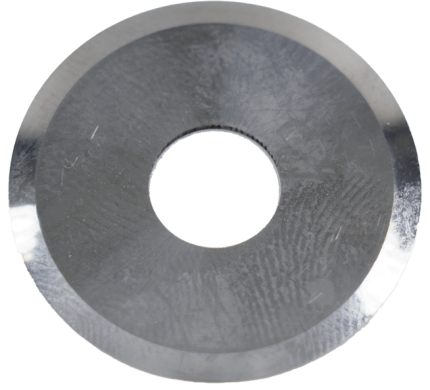

(2)Blade installation

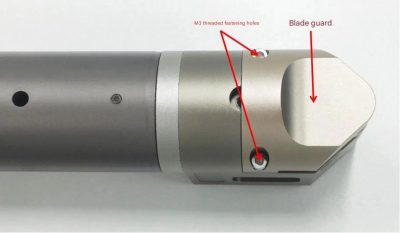

Use a hexagonal wrench to unscrew the screws in the threaded fastening holes and remove the blade cover.

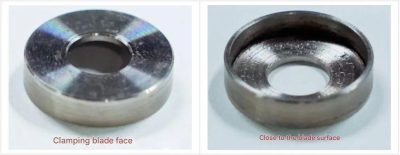

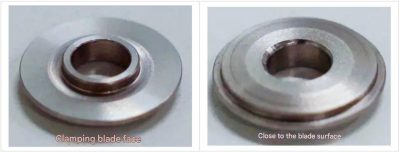

Clamp the blade between the blade fixing ring and the blade tightening wire. Pay attention to the clamping surface of the blade fixing ring and the blade tightening wire when clamping.

E2 and long zero round cutter head

Direct-insert and B3 round cutter heads

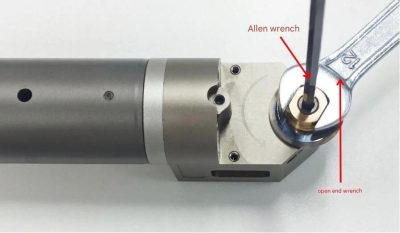

Use an open-end wrench to tighten the blade screw, and then use an Allen wrench to tighten the blade counterclockwise. Finally, tighten the blade cover (which can also be removed and replaced with a presser foot assembly), and the blade installation is complete.

(3)Presser foot installation

Align the M3 cylindrical countersunk hole of the presser foot with the M3 threaded fastening hole of the cutter head, and then tighten the screw with a hexagonal wrench.

Precautions

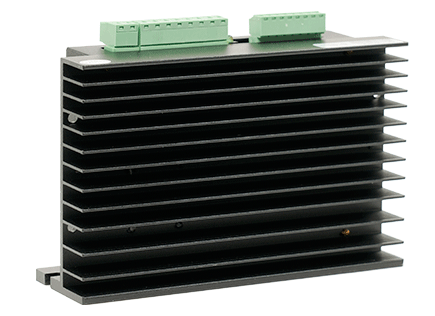

- The servo circular knife is shipped without a motor, which needs to be purchased separately. Before powering on, make sure the wiring is correct.

- Configure a separate switch power supply, and it is recommended to configure 24V15A or above.

- Do not use too much force when tightening the blade.

- Non-professionals are not allowed to disassemble the blade head.

- Pay attention to safety when installing the blade.

- Pay attention to the direction of blade rotation! If it rotates in the opposite direction, the blade is easy to loosen.

- It is required to connect clean and dry compressed gas. (For example, use a pneumatic triplex to filter, reduce pressure and refuel the gas to ensure the normal operation of the pneumatic actuator and prevent malfunctions due to impurities, excessive air pressure or lack of oil.)

Order Model

| Order Model | Perce91172 |

| Motor speed RPM | 0-3000 |

| Motor power/W | 100 |

| Overall dimensions/mm | W62/H377.5/D74 |

| Weight kg | 1.6 |

Delivery standard configuration

Servo round tool holder

E2 round cutter head

Circular blades

(multiple specifications)

Multi-edge blades

(multiple specifications)

A presser foot

with E2 round cutter head

* The servo circular knife is delivered without motor

Options and accessories

Powerful circular knife

Straight-in round cutter head

90 round cutter head

E2 round cutter head

B3 round cutter head

Circular blades

(multiple specifications)

Multi-edge blades (multiple specifications)

Ceramic blades

(multiple specifications)

Servo Motor

Drive

A presser foot

(with E2 round cutter head)

B presser foot

(with B3 round cutter head)

Presser foot

(with straight-insert round cutter head)

Reviews

There are no reviews yet.