Overview

The direct-insert servo vibration knife can process advertising KT board, foam board, ABS plastic, corrugated plastic board, corrugated paper, cardboard, gray cardboard, wire ring foot pad, carpet, seal ring, carbon fiber prepreg, etc.

The basic principle of the handle-type servo vibration knife is to cut the material by driving the blade to reciprocate at ultra-high speed by the motor, which is particularly suitable for cutting and shaping medium-density materials. With different blades, different materials can be processed.

The handle-type servo vibration knife has a heat dissipation device, which can easily cool the vibration knife.

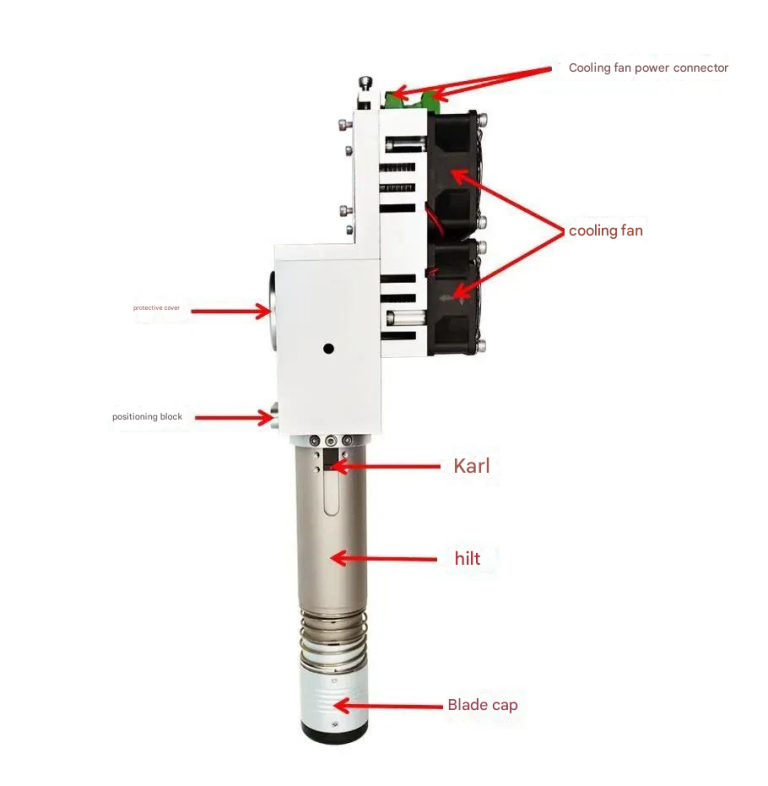

Component Description

Component Description

Power cord: Provides power

Cooling power connector: Powers the cooling fan

Cooling fan: Cools the motor components

Servo motor: Power element

Positioning block: Positions and fixes when used in conjunction with the knife holder

Card ear: Locks the knife handle

Knife handle: Vibrating knife blade

Knife head cap: Used to hold the material tight when cutting

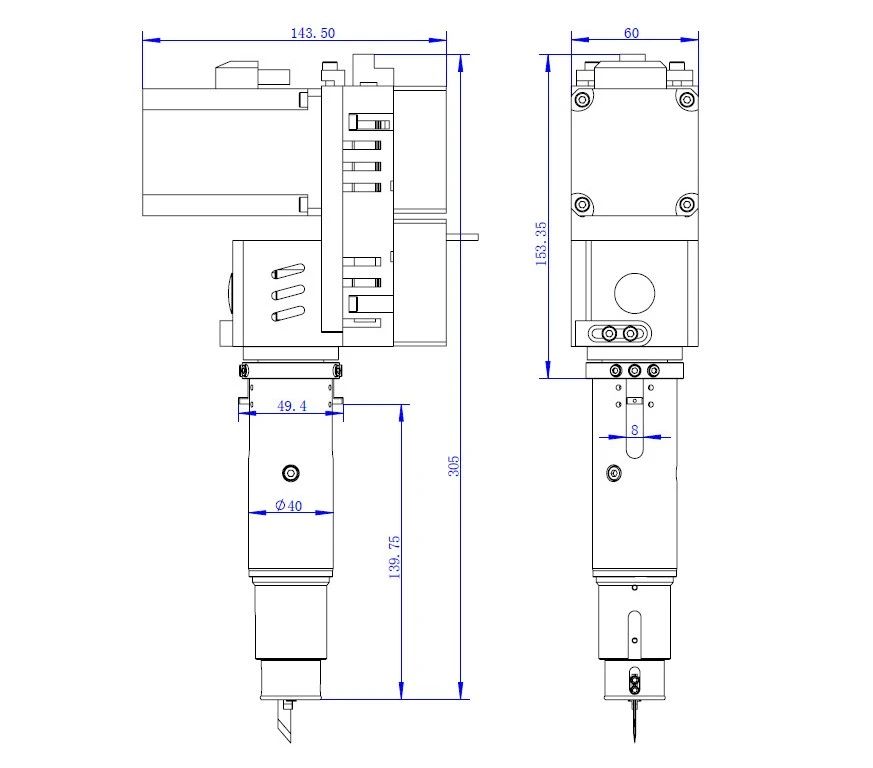

Installation Dimensions

Installation Dimensions

Instructions for use and debugging

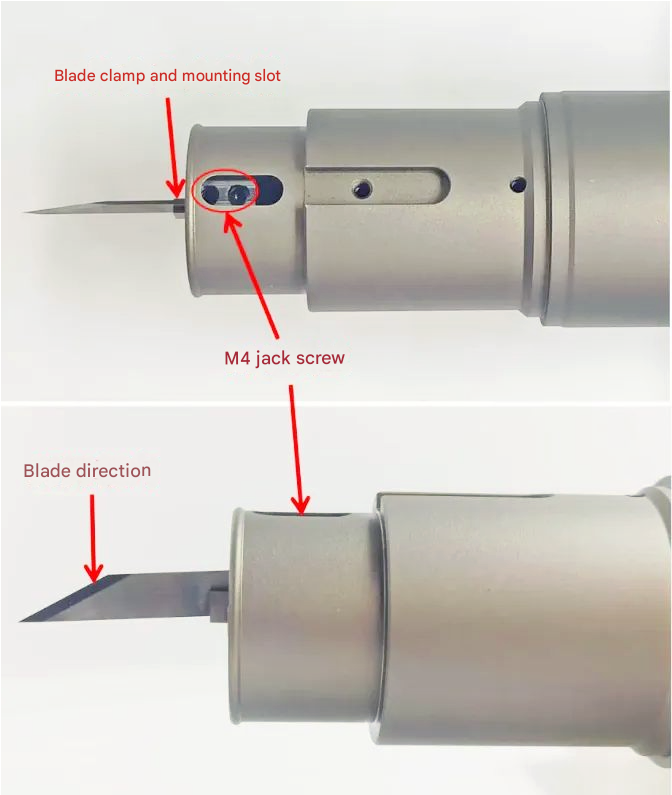

(1) Installation and removal of the blade cover

Align the guide rivet on the blade cover with the installation slot of the vibration handle, press the blade cover into the handle with a little force, and a “click” sound indicates that the blade cover is installed in place. Check whether the blade cover cylinder moves up and down smoothly.

When pulling out the blade cover, keep the blade cover and the handle in a straight line and pay attention to safety.

(2)Blade installation

Loosen the M4 screw and insert the blade in the direction shown in the figure; insert the blade until it stops (the insertion part is about 13mm); tighten the M4 screw and turn the shaft at the tail of the motor by hand to ensure that the blade can slide easily.

(3)Blade clamp removal

Method 1: Use a screwdriver to move the blade clamp back and forth until it loosens and can be removed (recommended).

Method 2: First clamp the waste blade with the blade clamp, then clamp the blade clamp with pliers and pull it out.

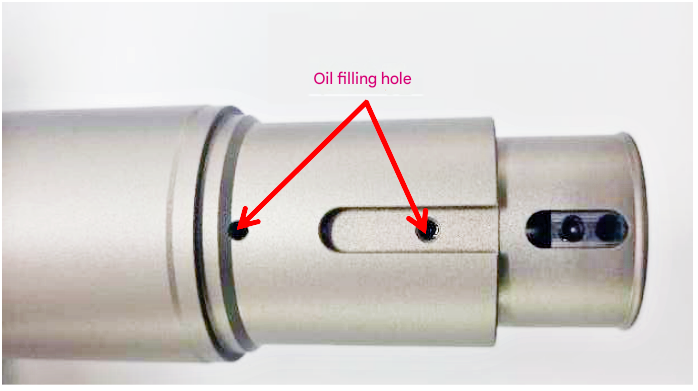

(4) Oiling and maintenance

Unscrew the top screw of the oiling hole and drip clean sewing machine oil or other liquid lubricant.

After the machine is finished working, use an air gun to clean up the small debris stuck to the cutter head to prevent the debris from entering the working area of the cutter head and causing the cutter head to get stuck.

If the cutter head is not used for a long time, oil needs to be added to the oiling hole and the cutter head needs to be left to cut for 5 minutes so that the sliding part of the cutter head can fully produce an oil film to reduce air corrosion.

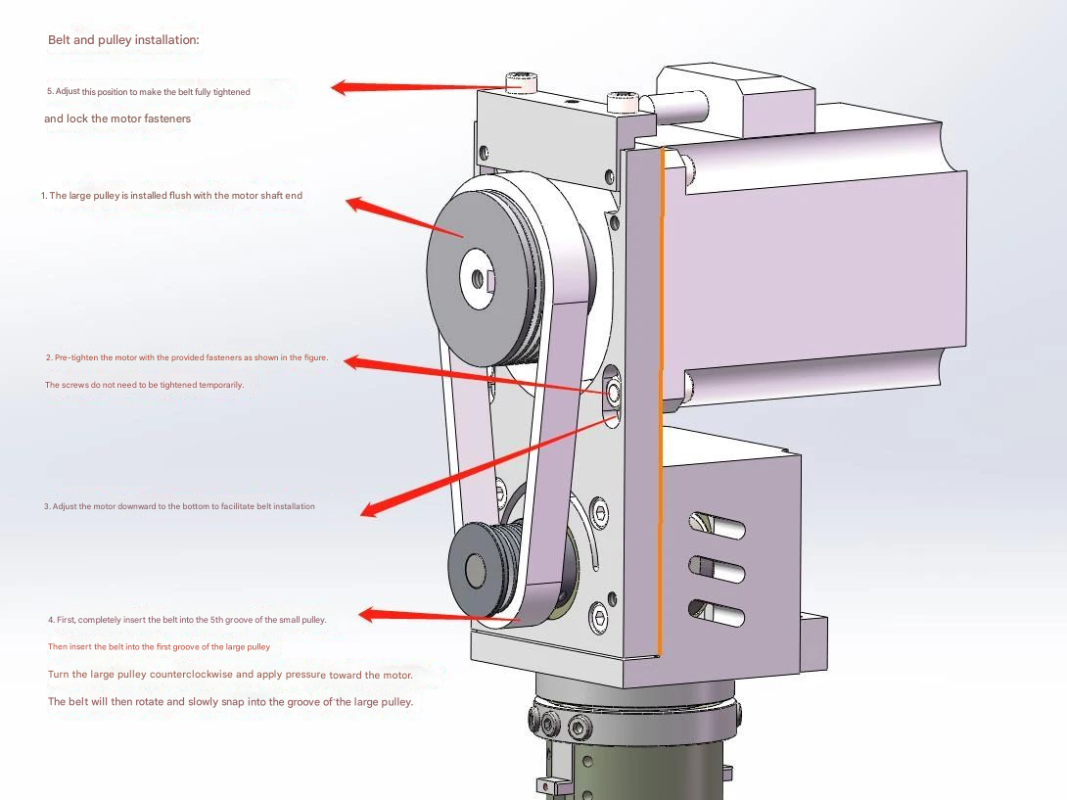

(5)Pulley installation and belt tensioning

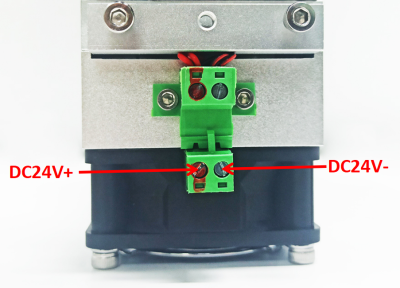

Wiring Instructions

Precautions

1. The recommended switch power supply is 24V2A or above

2. Before powering on, make sure the wiring is correct

3. Non-professionals are not allowed to disassemble the blade

4. Pay attention to safety when installing the blade and blade cap

Product Parameters

| Order Model | Perce 91249 servo oscillating tool-5mm |

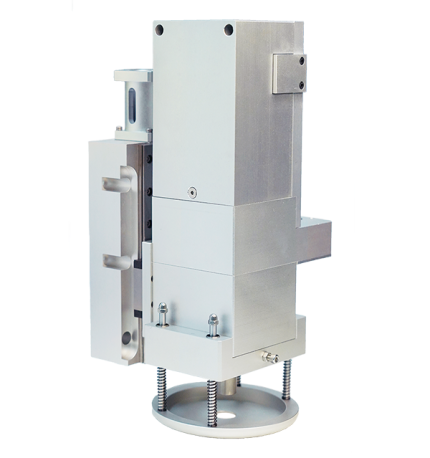

| overall dimensions/mm | W143.5/H305/D60 |

| weight | 1.86(without motor) |

Multi-faceted appearance

Shipping Configuration

Perce 91249 Servo Oscillating Knife - 5mm (shipped without servo motor)

Perce 95010 Blade Clip

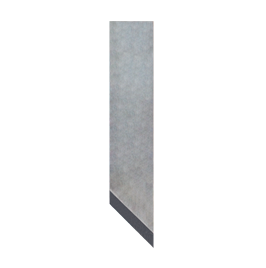

Perce 95014 Single Edge Blade

Optional accessories

-5.png)

Perce 95010 Blade Clip (0.63/1/1.5/2mm)

Perce 95011 Blade Cap

-2.png)

Perce 95014 Single Edge Blades (Various Sizes)

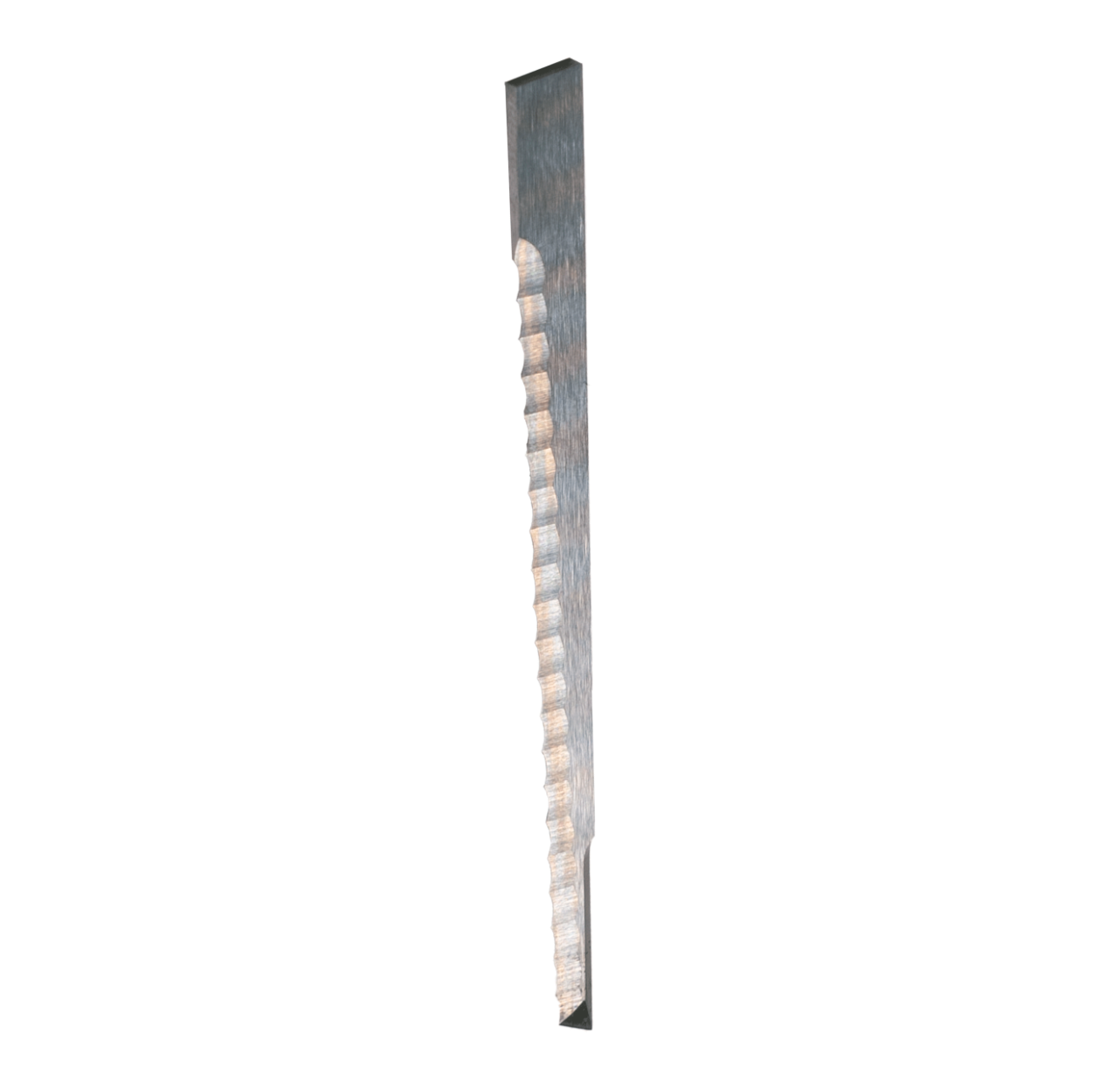

Perce 95034 Serrated Blade

-4.png)

Perce 95015 Double Edge Blades (Various Sizes)

Perce 95168 Blade Cap Plate

组合刀头带振动刀)-430x573.png)

Reviews

There are no reviews yet.