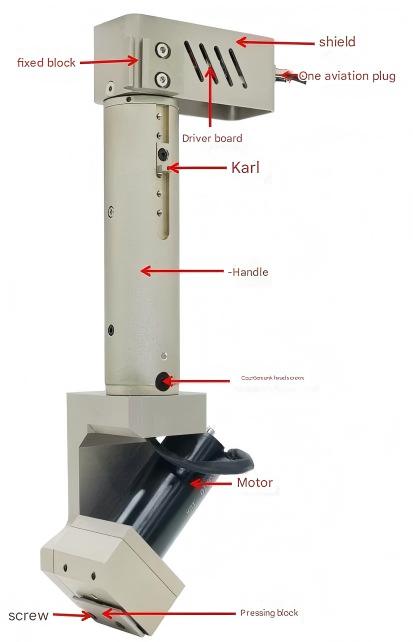

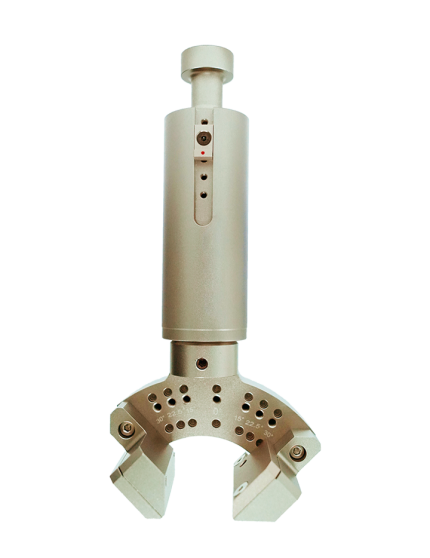

Product appearance and overview

The vibrating bevel cutter can clamp the blade to cut V-shaped grooves and bevels, and process soft glass, PVC, honeycomb board, KT board, vertical corrugated paper, gray paperboard and other materials. The basic principle of the vibrating bevel cutter is to drive the blade to reciprocate at ultra-high speed through the motor to cut the material. With different blades, different materials can be processed.

Component Description

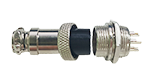

Aviation plug: connect to power supply.

Fixed block: connect to the blade support rod.

Lock: used to lock the blade handle.

Brace: vibration bevel blade.

Countersunk screw: lock the blade head.

Motor: power element.

Block: press the blade.

Screw: lock the blade.

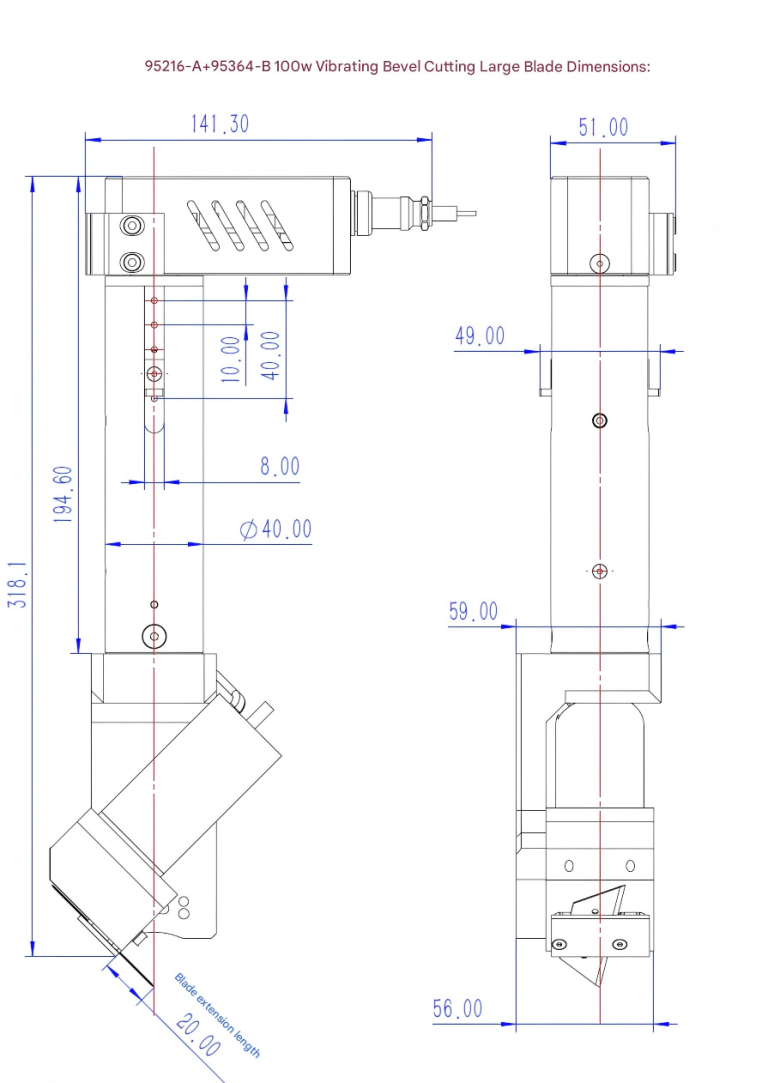

Installation Dimensions

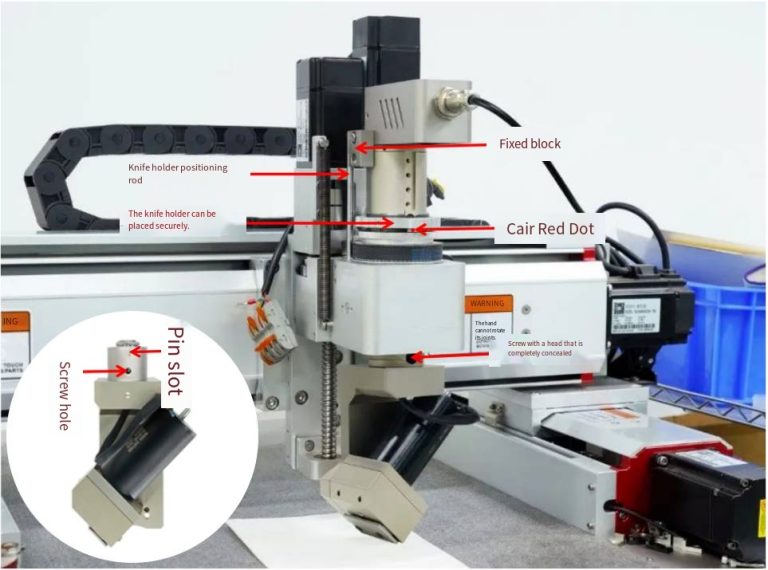

Installation Diagram

Installation process of 91265 vibrating bevel cutter:

1. Use a wrench to remove the countersunk screws (two in front and back) and separate the cutter head and the handle;

2. Install the handle, align the red dot of the handle ear with the notch of the tool holder locking wire, align the groove of the handle fixing block with the tool holder positioning rod, put the handle in and tighten the tool holder locking wire;

3. Install the blade (see the following 05 usage and debugging instructions for details), it is safer to install the blade first and then install the machine;

4. Install the cutter head, the direction of the cutter head pin slot is consistent with the direction of the red dot of the handle ear, the screw hole of the cutter head is connected with the screw hole of the handle, install the locking countersunk screws (two in front and back) to complete the installation.

Instructions for use and debugging

Blade installation

Loosen the two screws, align the blade and place it parallel to the blade slot. The blade should extend 20mm. Pay attention to the direction of the blade when installing.

After installing the blade, tighten the two screws. When tightening, pay attention to the gap between the blades. If the gap is too large, the blade will fall out easily. (You can loosen the screws to adjust the blade height).

Perce 91265 Oscillating Miter Cutter - Large Blade Installation

Perce 91265 Oscillating Miter Cutter - Small Blade Installation

Blade removal

Loosen the two screws and the blade can be removed after it is loose.

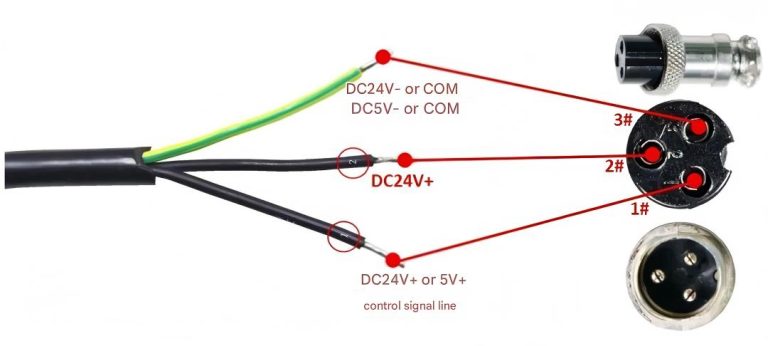

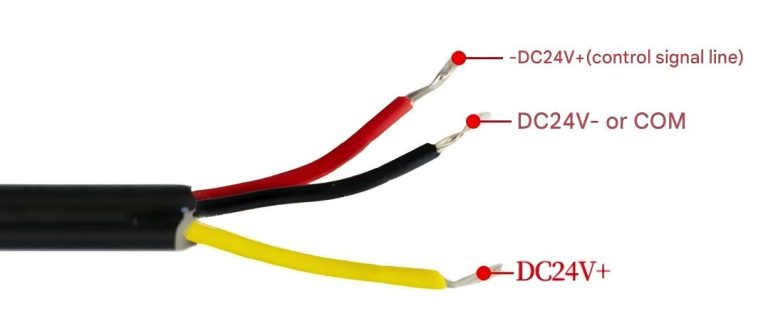

Wiring Instructions

The 91265 vibrating bevel cutter requires a switching power supply of 24V10A or above. It is recommended to use an independent power supply.

| Yellow-green line | DC24V-orCOM DC5V-orCOM |

| Black wire No. 2 | DC24V+ |

| Black wire No. 1 | DC24V+or5V+ Control signal line |

| Red Line | DC24V+ (control signal line) |

| Black wire No. 2 | DC24V- or COM |

| Black wire No. 1 | DC24V+ |

Precautions

1. Non-professionals are not allowed to disassemble the blade.

2. Configure a separate switch power supply, it is recommended to configure 24V10A or above

3. Before powering on, confirm that the wiring is correct

Order Model

Product Parameters

| Order Model | Perce91265 |

| Cutting thickness/mm | 12 |

| Motor power/W | 100 |

| Overall dimensions/mm | W141.3/H317.5/D59 |

| Weight | 1.5 |

Shipping Configuration

Oscillating bevel cutter

Optional accessories

Oscillating Bevel Head

Single Edge Blade

Trapezoidal Blade

Aviation Plug

100W motor

Reviews

There are no reviews yet.