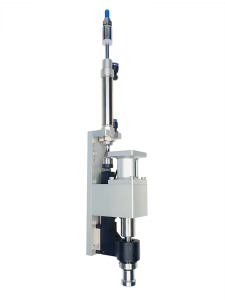

Overview

Perce 91182 non-following slotted punch are composed of Perce 95098 non-following servo punch holders that clamp round punches and needle punches respectively. They can punch leather, imitation leather, PU, PVC, EVA, SBR, cloth, cardboard, kraft paper and other materials.

Non-following V punch and non-following slotted punch are driven by the motor to rotate the spindle at high speed, and the cylinder drives the spindle to move up and down quickly, so that the punch can punch and cut the material.

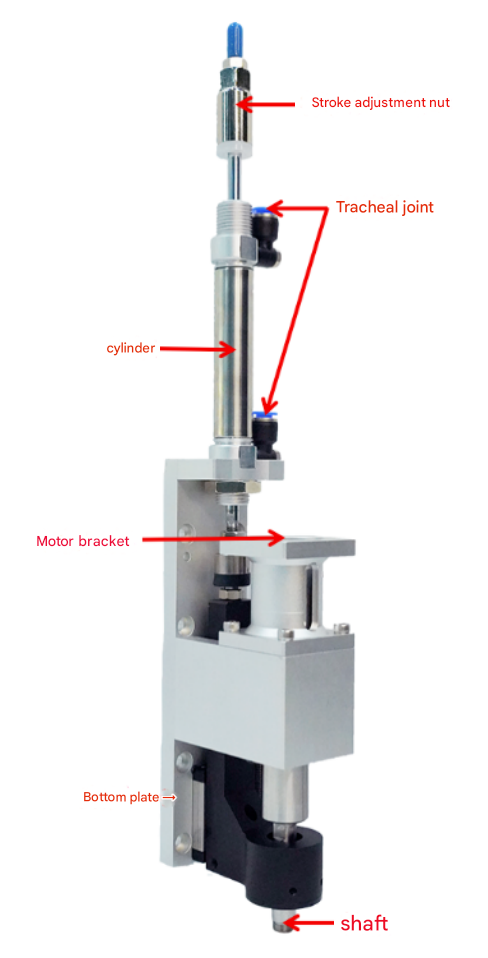

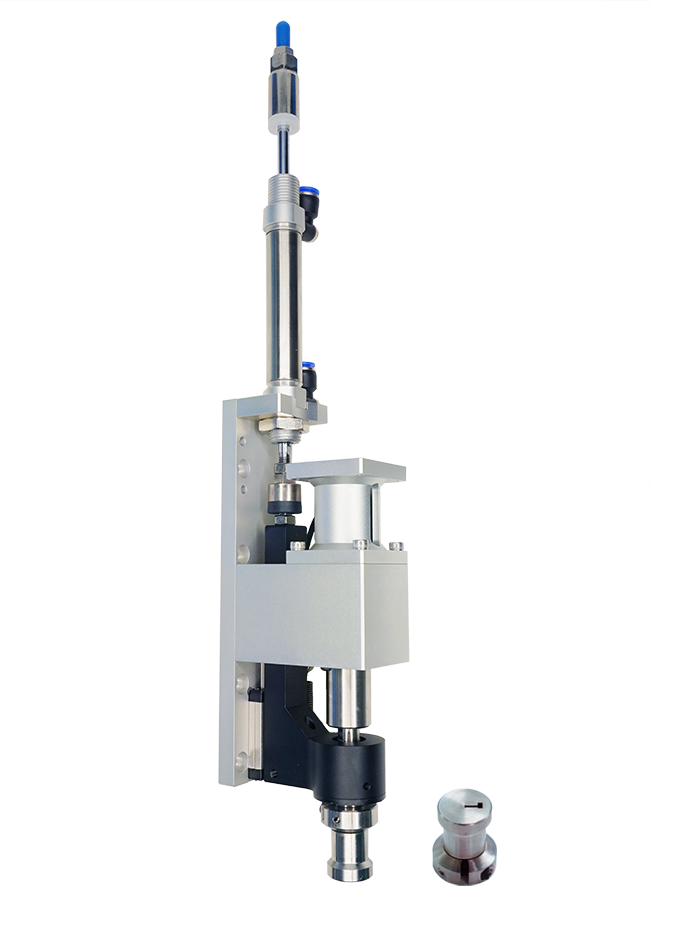

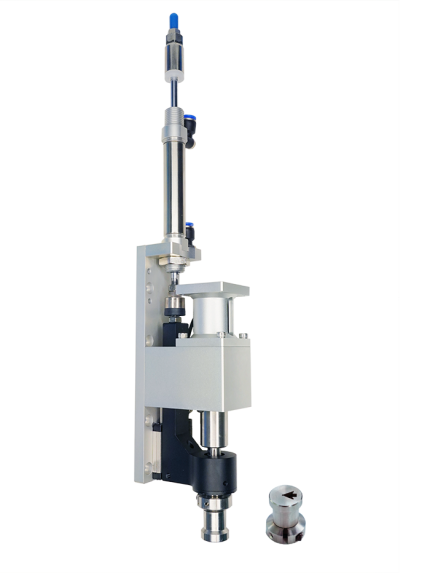

Component Description

Stroke adjustment nut: cylinder stroke fine-tuning device

Trachea joint: solenoid valve air circuit access

Motor bracket: motor mounting position

Rotation limit switch: punching angle control element

Base plate: used to install and fix the punch body

Punch bracket: punch clamping device

Punch: clamping punch

Installation Diagram

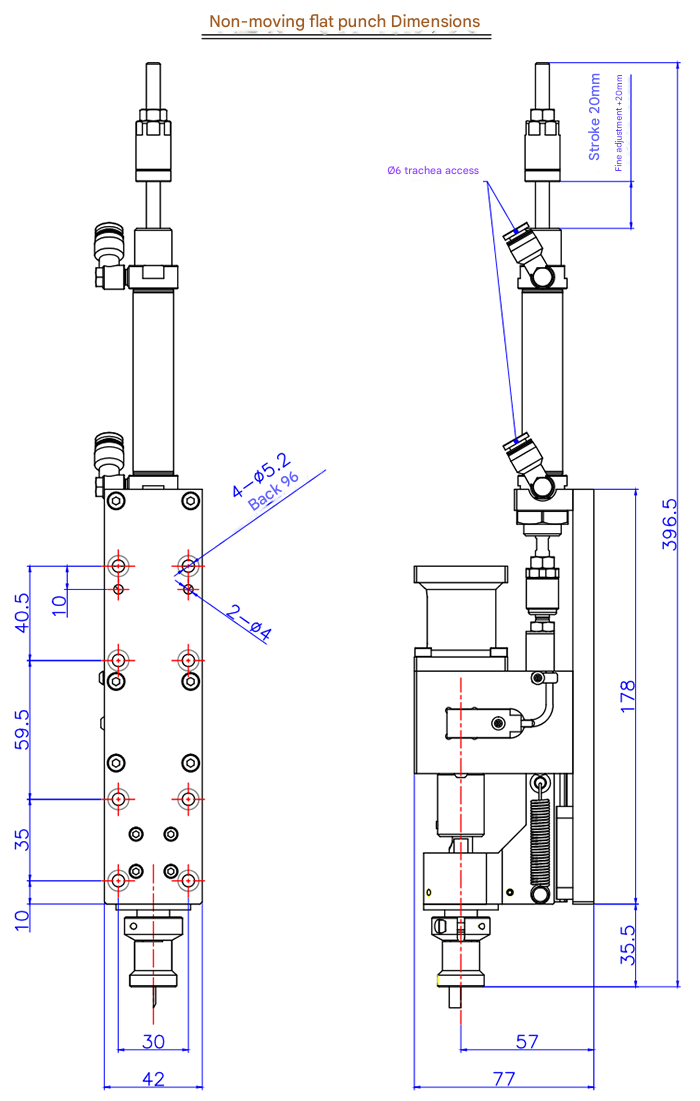

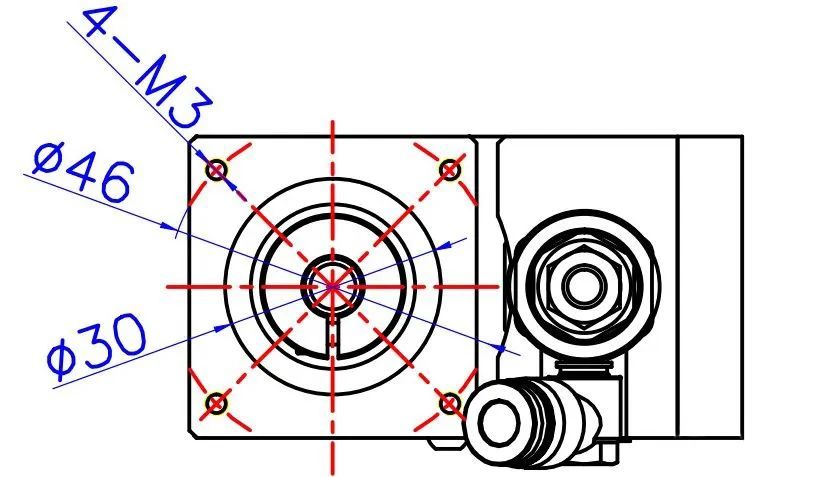

Installation Dimensions

Instructions for use and debugging

(1)Installation and debugging

Use 4 M5 screws to fix the Perce 91181 non-following V punch on the equipment mounting plate. The installation height should be no higher than 20 (+1~+5) mm from the work surface. The motor should be correctly wired and the cylinder should be connected to the air pipe. Depending on the punching effect, the stroke adjustment nut can be fine-tuned appropriately until the best punching effect is achieved.

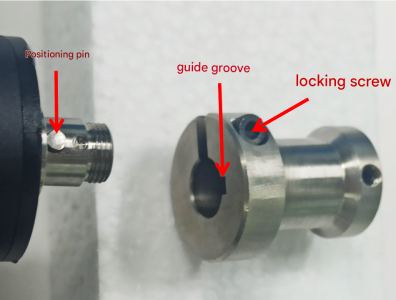

(2)Punch installation and removal

Punch installation: Align the punch guide groove with the positioning pin and insert it, then use a hexagonal wrench to tighten the screwf

Punch removal: Be careful not to clamp the drive shaft to remove the punch, but fix the flat position of the wrench and then remove the punch.

(3)Oiling and maintenance

Lubricating the guide rails at regular intervals can reduce wear on the guide rails and make them work better.

Wiring Instructions

| Black | Signal line |

| Blue | DC24V- |

| Brown | DC24V+ |

Precautions

1. Before powering on, make sure the wiring is correct

2. The incoming air pressure is not higher than 0.6MPa

3. Clean and dry compressed gas must be connected. (For example, use a pneumatic triplex to filter, reduce pressure and add oil to the gas to ensure the normal operation of the pneumatic actuator and prevent malfunctions due to impurities, excessive air pressure or lack of oil.)

Product Parameters

| Order Model | Perce 91181 |

| Stroke/mm | 20 |

| Cutting thickness/mm | Different punches can cut different thickness |

| overall dimensions/mm | W42/H396.5/D77 |

| weight kg | 1.1 |

Multi-faceted appearance

Shipping Configuration

Perce 95098-C1 Non-Servo Punch Holder

Perce 95041 Slotted Punch

-1-182x300.png)

Perce 95025 Slotted Punch (Multiple Specifications)

Optional accessories

-1.png)

Perce 95024V punch (multiple specifications)

-182x300.png)

Perce 95025 Slotted Punch (Multiple Specifications)

Perce 95041 Slotted Punch

Perce 95042 V Punch

Perce 95043 Round Punch

硬质一字冲子.png)

Perce 95044 Hard Slot Punch (3/5mm)

Perce 95048 Needle Punch

-ER圆冲头-1.png)

Perce 95049 ER round punch (3/5/8mm)

Reviews

There are no reviews yet.