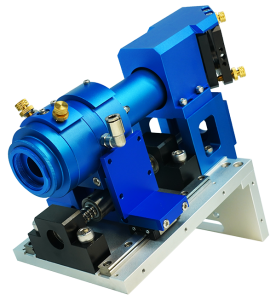

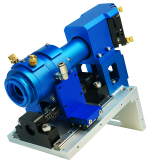

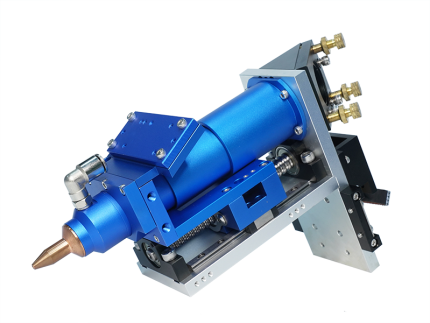

The SCT hybrid cutting head generates heat after focusing the laser beam to melt the surrounding materials and achieve cutting.

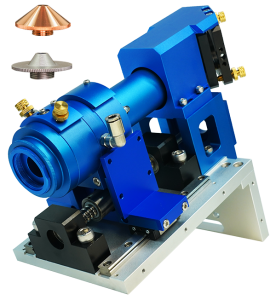

The SCT hybrid cutting head adopts a double drawer structure with a combination of long and short focal lengths. It can easily replace focusing lenses with different focal lengths to achieve processing of different materials, such as stainless steel, carbon steel, galvanized sheet and other metal materials; acrylic, density board, wood and other non-metal materials.

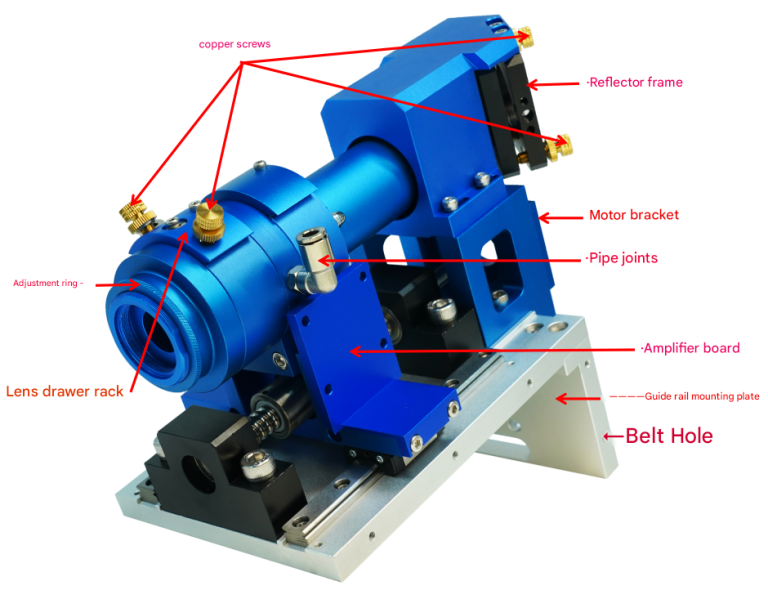

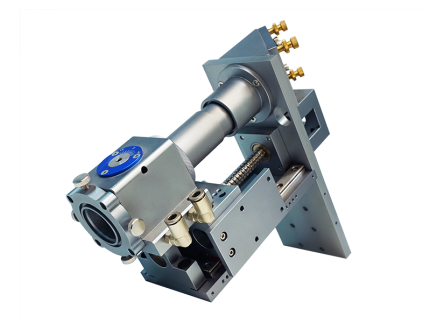

Component Description

Guide rail mounting plate: fix the body

Belt hole: install belt buckle

Motor bracket: install motor

Amplifier plate: install amplifier

Reflector bracket: install reflector

Lens drawer: Install focusing lens

Pipe joint: Connect water cooling pipe

Adjustment ring: Adjust nozzle height

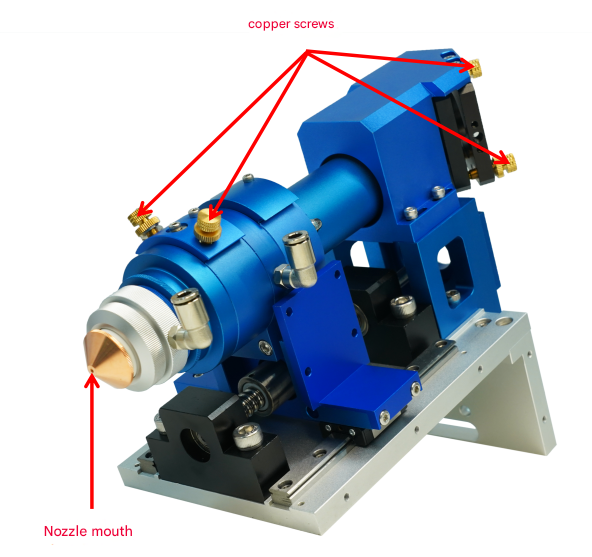

Copper screw: Adjust light

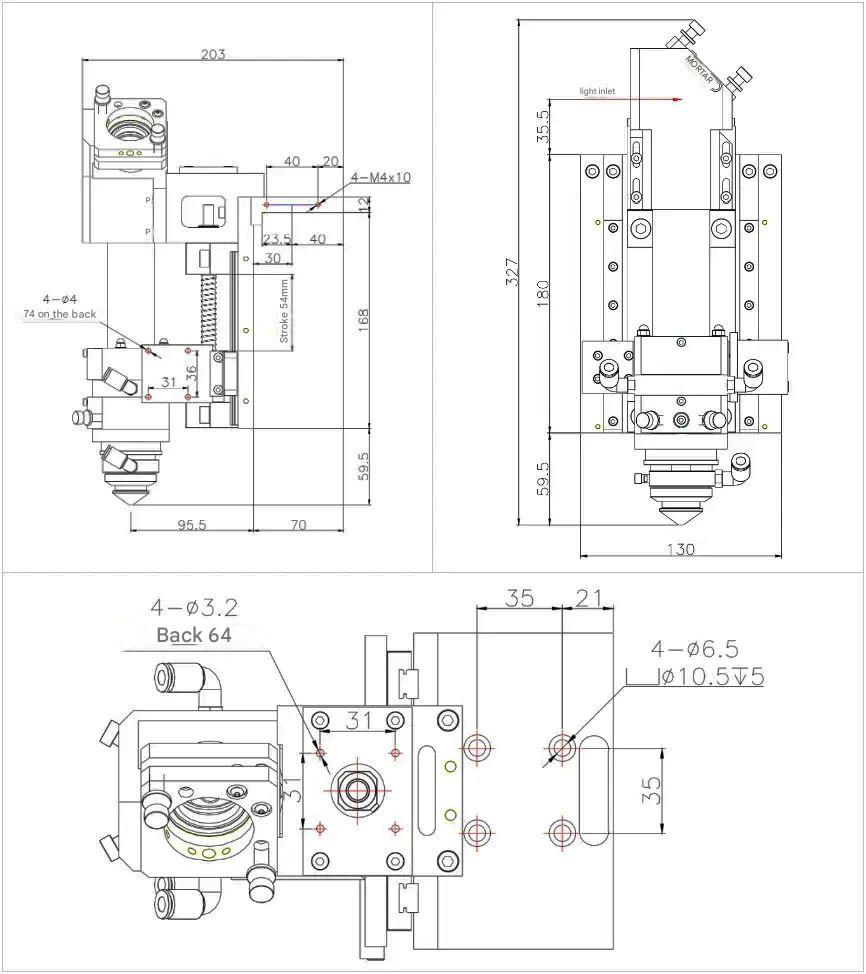

Installation Dimensions

Instructions for use and debugging

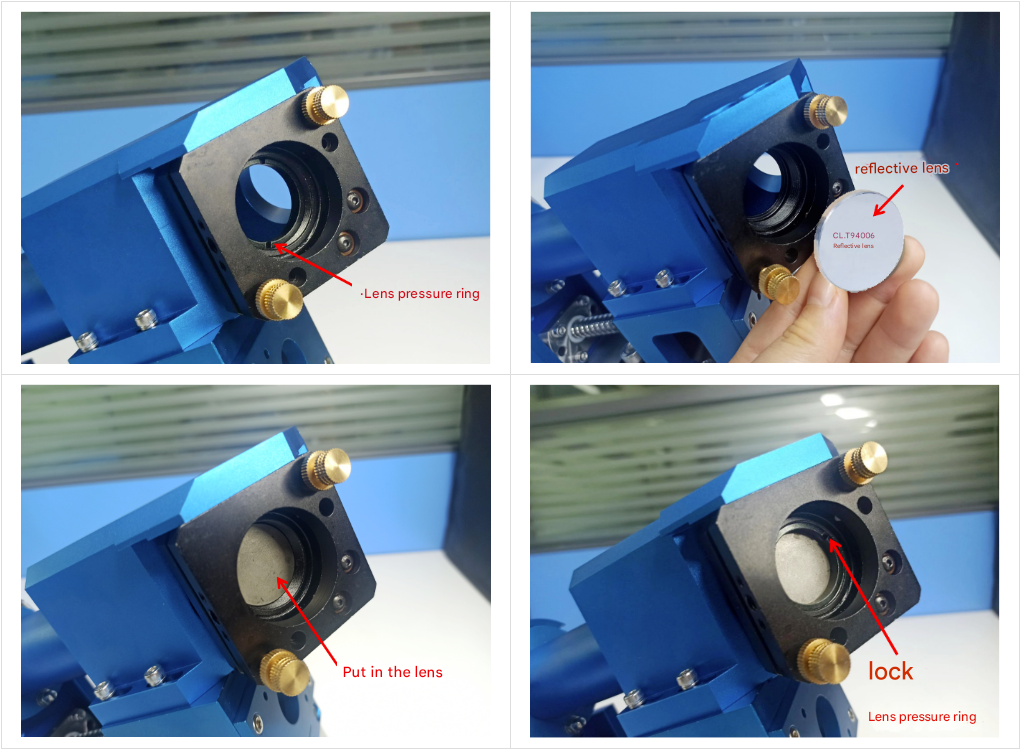

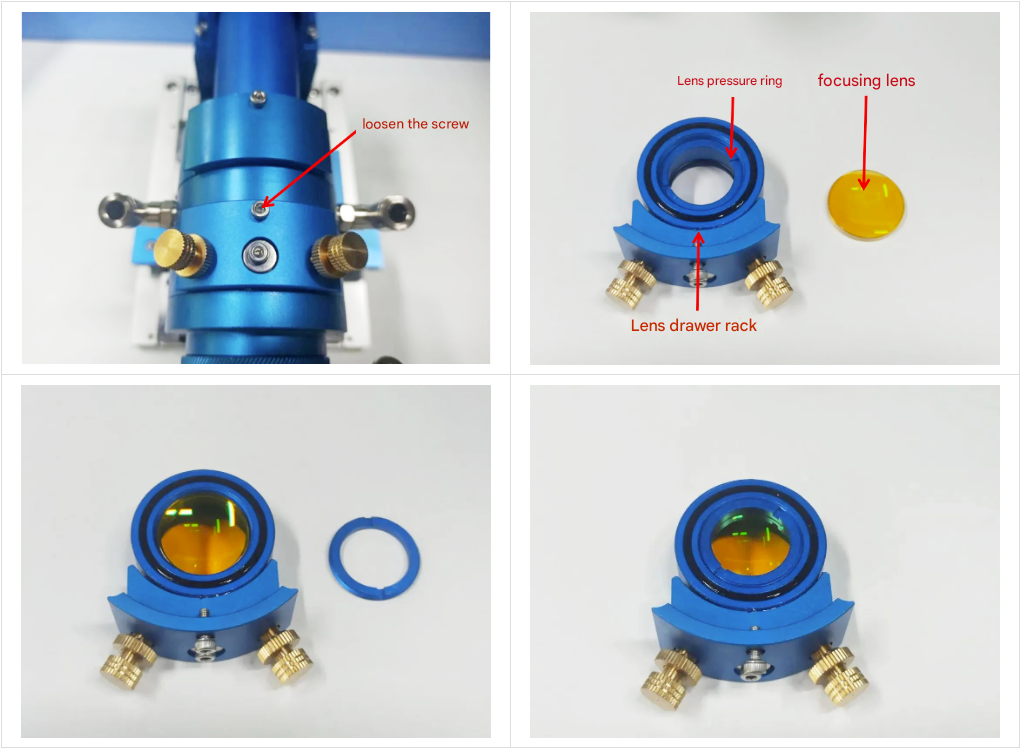

Lens installation

(1) Reflector lens installation

Use a tool to remove the lens pressing ring of the reflector frame, put the reflector lens into the lens hole (mirror surface facing inward, back surface facing outward), press it flat, and after ensuring it is flush, lock the lens pressing ring.

(2) Focusing lens installation

First loosen the screws, take out the lens drawer, then use the tool to remove the lens pressing ring, put the focusing lens into the lens hole, press it flat, and after ensuring it is flush, lock the lens pressing ring to complete the lens installation. (The hybrid cutting head has a double drawer structure, which can easily replace the focusing lens with different focal lengths, supporting 63.5/101.6mm focal length)

(3)Adjust the light

Adjust the light by fine-tuning the copper screws of the reflector frame and the lens drawer frame. Adjust the reflector first, then adjust the focusing lens. If the light beam passes through the nozzle correctly, the light adjustment is correct.

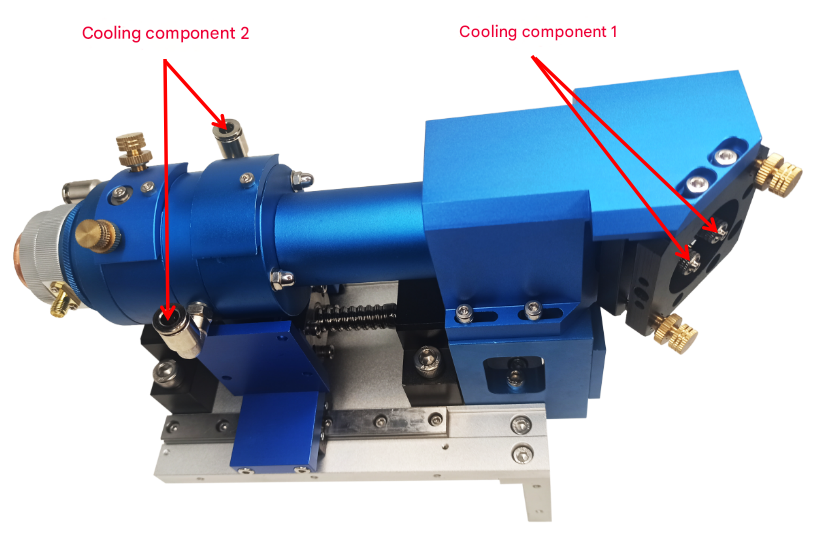

2.Water cooling components

Laser equipment will continuously generate high temperatures when working. The cooling component can be connected to a cooling pipe (the connecting medium can be water or gas) for circulating cooling and temperature control to protect the machine.

Cooling component 1: for the high temperature generated by the reflector. (The lens pressing piece on the reflector frame can be removed and replaced with a cooling component)

Cooling component 2: for the high temperature generated by the focusing mirror.

Maintenance

- Regularly maintain the Z-axis transmission system to ensure it is clean and lubricated.

- Regularly check the lens in the laser head to ensure it is clean.

- Regularly check the nozzle. If there is any damage, please replace it in time.

Precautions

- Non-professionals are not allowed to disassemble.

- You need to install the upper and lower limit switches of the Z axis by yourself. After installation, make sure that the upper and lower limit switches of the Z axis work normally and effectively before turning on the machine.

- After the laser equipment is turned on, invisible light will be generated, and professional personnel are required to operate it. Please pay attention to safety.

- It is required to connect clean and dry compressed gas. (For example, use a pneumatic triplex to filter, reduce pressure and refuel the gas to ensure the normal operation of the pneumatic actuator and prevent malfunctions due to impurities, excessive air pressure or lack of oil.)

Order Model

Product Parameters

| Order Model | Perce 91001 |

| Reflector diameter/mm | 25/30 |

| Focusing lens diameter/mm | 25 |

| Supported focal length/mm | 63.5/101.6 |

| Stroke/mm | 54 |

| Overall dimensions/mm | W130*H327*D203 |

| Weight kg | 3.6 |

Product Information

mixed cut head blue

*Sensors and water cooling components must be purchased separately

Product accessories

94002 Ceramic Ring

94001 Sensor

94002 Ceramic Ring

94003 Copper Mouth

94004 aluminum nozzle

94005 Focusing lens

94006 Reflective lens

Four Three Drive

94008 Driver

94012 coupling

94011 Quick Connector

94027 belt buckle

94009-B Water Cooling Assembly

94015 Dimming Cross

Reviews

There are no reviews yet.