Overview

Perce 91152 high-speed punch, the motor drives the spindle to reciprocate up and down, so that the punch can punch and cut materials. It can punch and cut genuine leather, imitation leather, PU, PVC, EVA, SBR, cloth, cardboard, kraft paper and other materials.

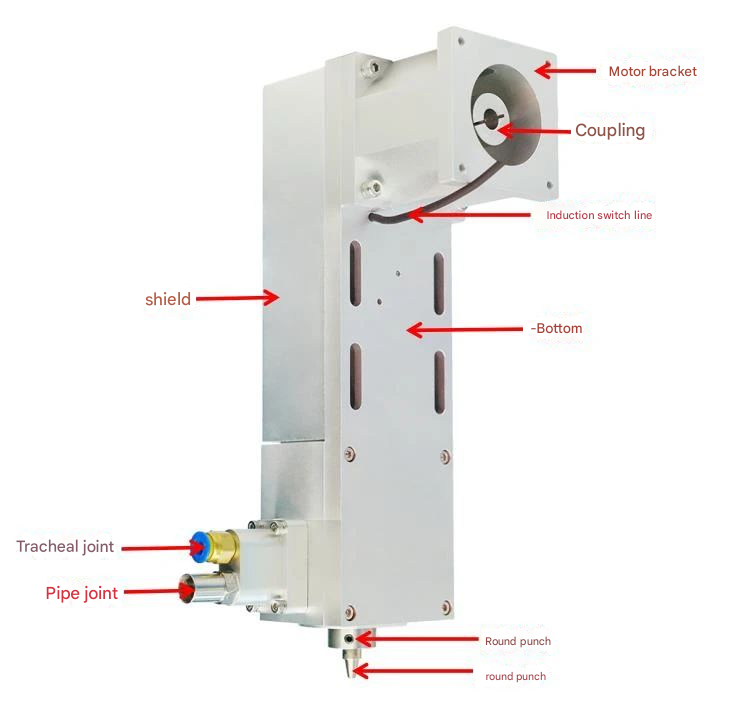

Component Description

Motor bracket: Install the motor

Coupling: Used for connecting the motor

Induction switch line: When the motor stops working, the punch rod (Z-axis direction) is raised to the highest point, and the punch below is away from the table to the maximum distance.

Base plate: Used to install and fix the high-speed punch body

Round punch: Clamp the punch

Round punch: Punch the material

Pipe joint: Connect the waste chip collection device

Gas pipe joint: Connect the gas

Shield: Protect the internal parts of the high-speed punch

Installation Diagram

Installation Dimensions

Instructions for use and debugging

(1)Installation and debugging

Unscrew the four cover screws, remove the cover, swing the cam, wait until the punch is completely in contact with the table, then determine the installation height of the bottom plate, fix the high-speed punch body to the equipment installation plate with four fixing screws, and finally reinstall the cover.

(2)Punch installation

Loosen the top screw, insert the punch, and then tighten the top screw.

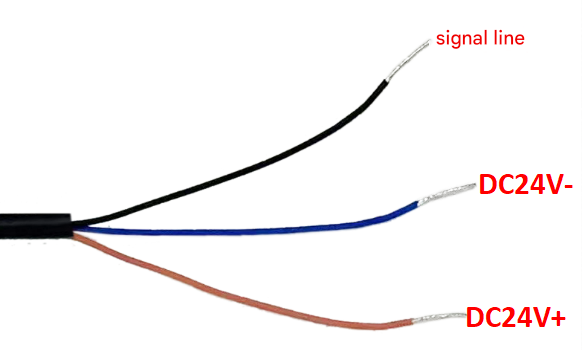

Wiring Instructions

| Brown | DC24V+ |

| blue | DC24V- |

Precautions

1. Before powering on, make sure the wiring is correct

2. Clean, dry compressed gas must be connected. (For example, use a pneumatic triplex to filter, reduce pressure, and refuel the gas to ensure the normal operation of the pneumatic actuator and prevent malfunctions due to impurities, excessive air pressure, or lack of oil.)

Product Parameters

| Order Model | Perce 91152 |

| cutting thickness/mm | different punches can cut different thicknesses |

| overall dimensions/mm | W110/H243/D109 |

| weight kg | 2 |

Shipping Configuration

Perce 91152 High Speed Punch

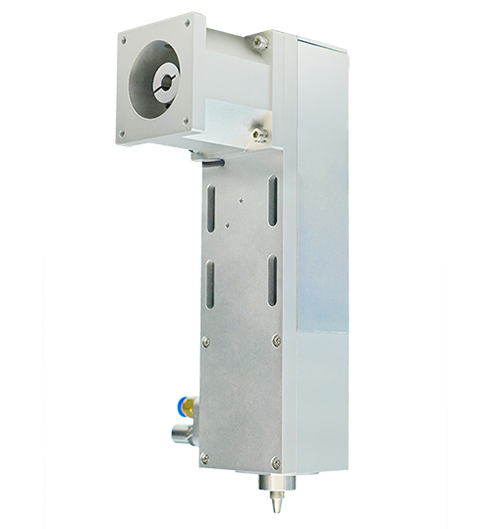

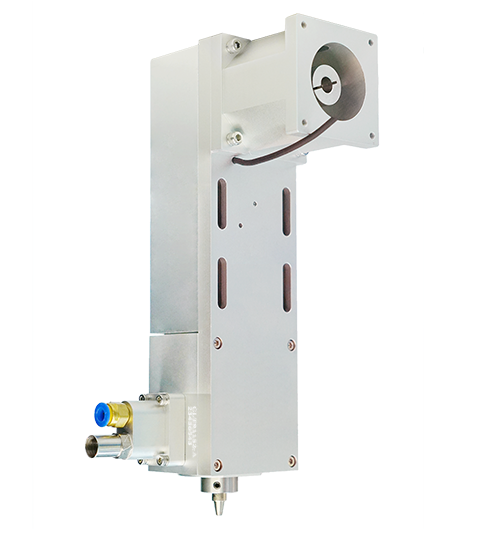

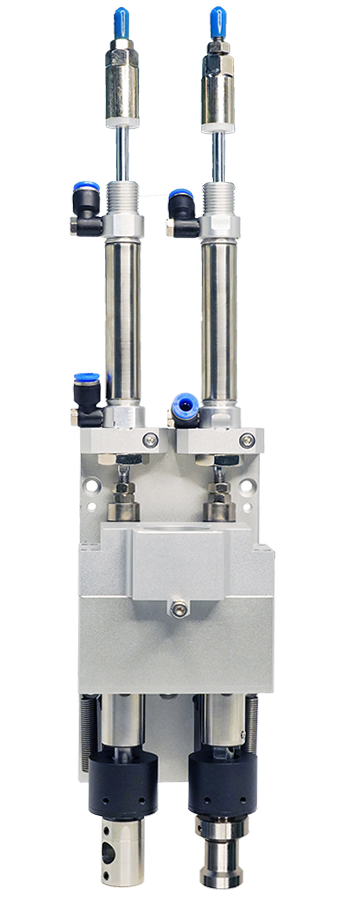

Multi-faceted appearance

Reviews

There are no reviews yet.