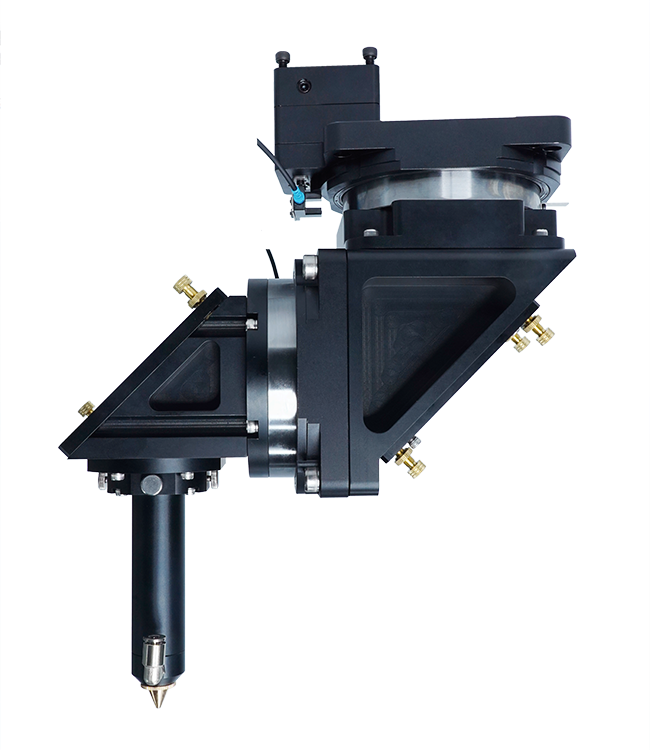

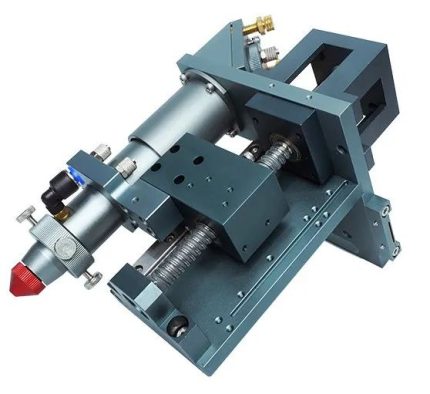

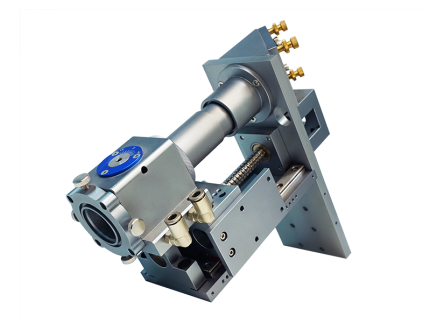

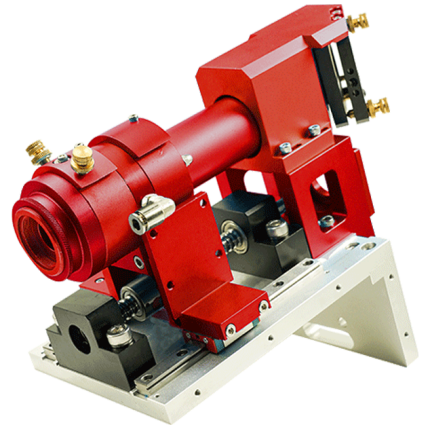

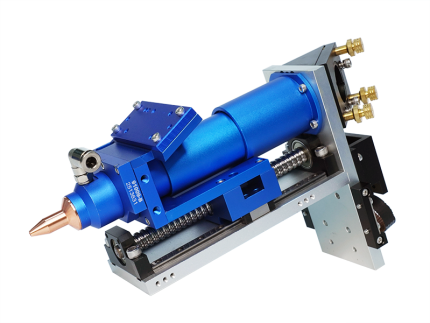

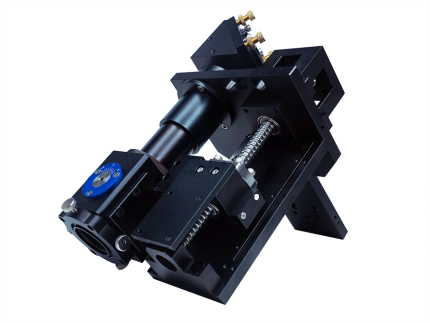

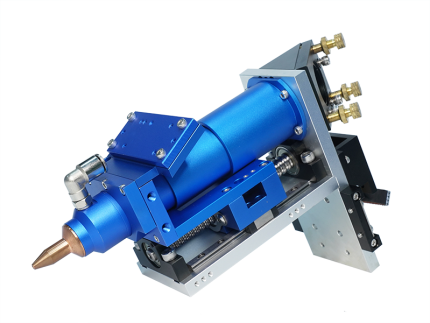

The laser head rotates along two axes. The laser beam enters the inner cavity of the cutting head through the reflector and through the focusing lens, the energy of the laser beam is concentrated at a certain point. The surrounding materials are melted at high temperature to form processing marks and achieve the cutting effect.

In response to the problems of ordinary laser heads such as inflexible rotation and few degrees of freedom, the dual-axis rotating laser head optimizes the multi-degree-of-freedom rotation control method of the laser cutting head. It can perform multi-degree-of-freedom rotation in three-dimensional space and realize cutting processing of any shape such as helmets, masks, and car interiors.

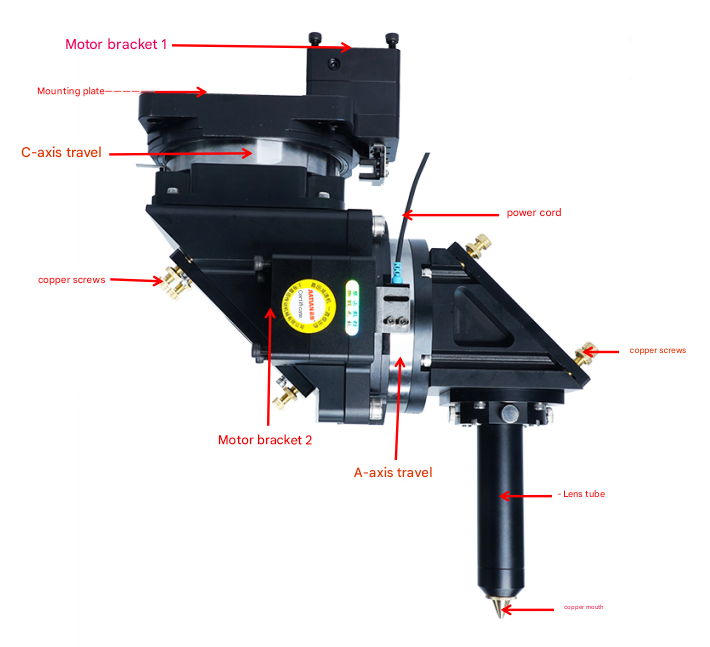

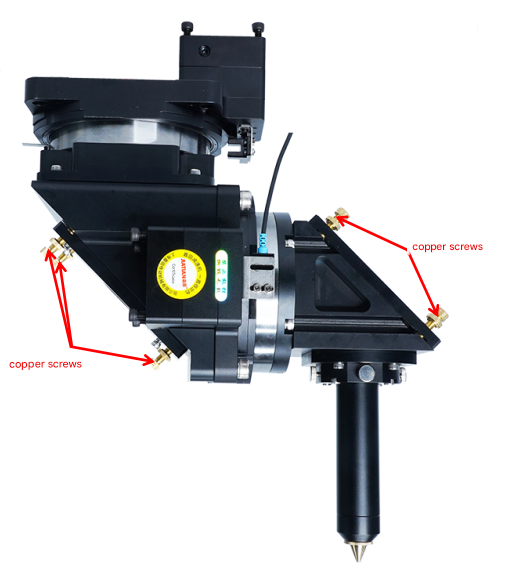

Component Description

Mounting Plate:Fixed body

Motor bracket:Mounting the Motor

Copper screws:Light adjustment

Reflector frame:Installing the reflector

Displacement sensor mounting plate:Installing the displacement sensor

Lens tube:Install the focusing lens

Copper Mouth:Beam ejection port

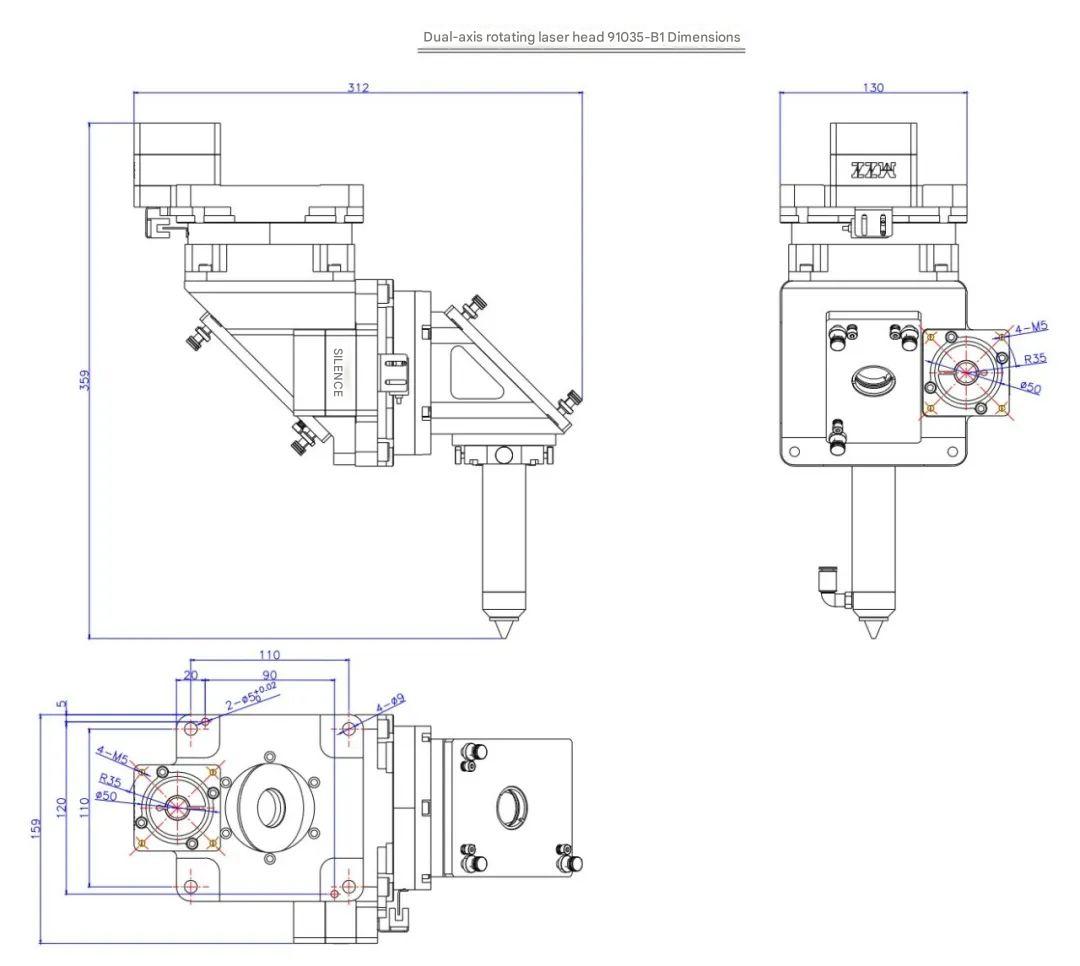

Installation dimensions

Instructions for use and debugging

Lens installation

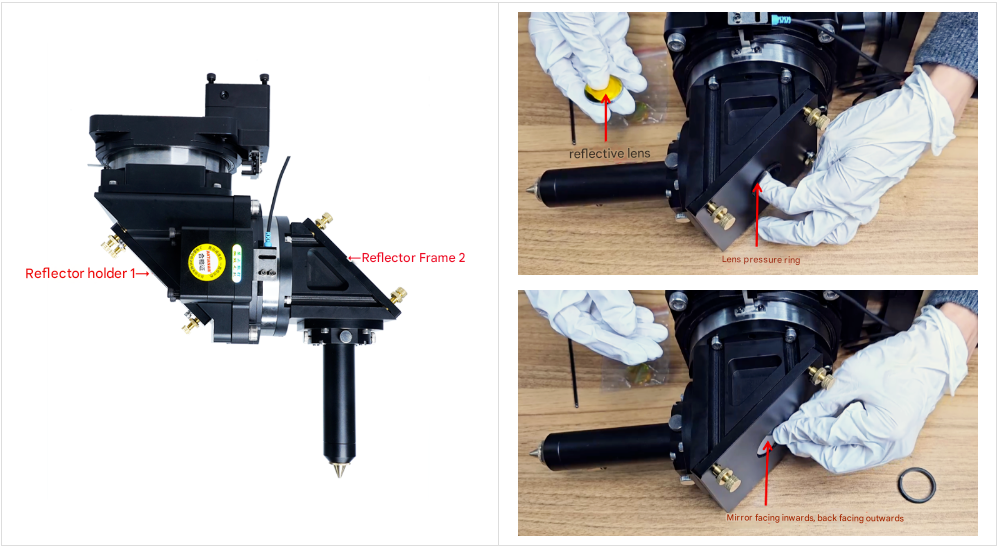

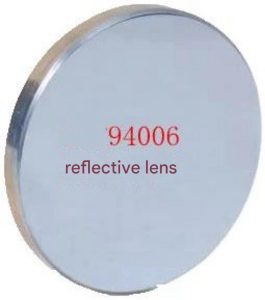

(1) Installation of reflective lens

Remove the lens pressing ring on the reflector frame by rotating it, put the reflector lens into the lens hole (mirror surface facing inward, back surface facing outward), press it flat, and after ensuring it is flush, rotate and lock the water cooling assembly. Two reflector lenses need to be installed, and they can be installed one by one.

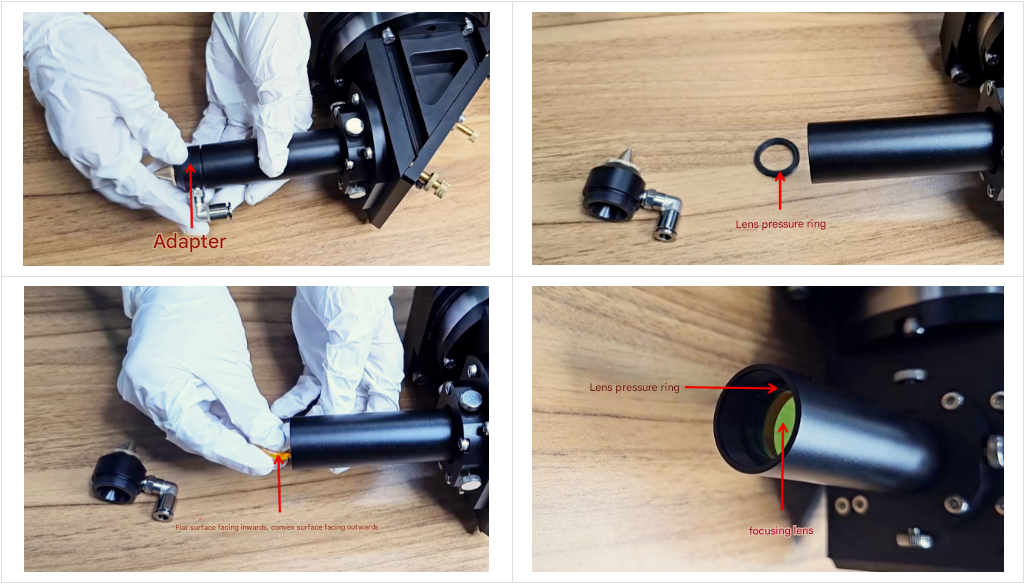

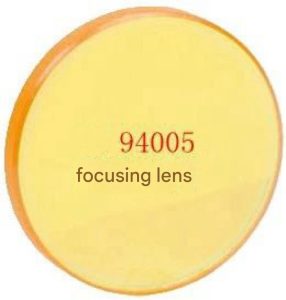

(2) Focusing lens installation

First loosen the holding screws, take out the lens barrel, use a tool to rotate and take out the lens pressing ring, put the focusing lens flat into the lens barrel and press it against the O-ring. After ensuring it is flush, lock the lens pressing ring to complete the installation of the focusing lens.

Adjust the light

Adjust the reflector first, then adjust the focusing mirror. If the light beam passes through the nozzle correctly, the light adjustment is correct. (Note! After the laser equipment is turned on, it will produce invisible light, which requires professional operation, please pay attention to safety!) Adjust the reflector: adjust the light by fine-tuning the copper screws. Adjust the focusing mirror: first loosen the four fixing screws, then fine-tune the four flat-end hand screws to adjust the focusing mirror light, and tighten the fixing screws after completion.

Maintenance

- Regularly maintain the A-axis and C-axis transmission systems to ensure they are clean and lubricated.

- Regularly check the lens in the laser head to ensure it is clean.

- Regularly check the nozzles. If there is any damage, please replace it in time.

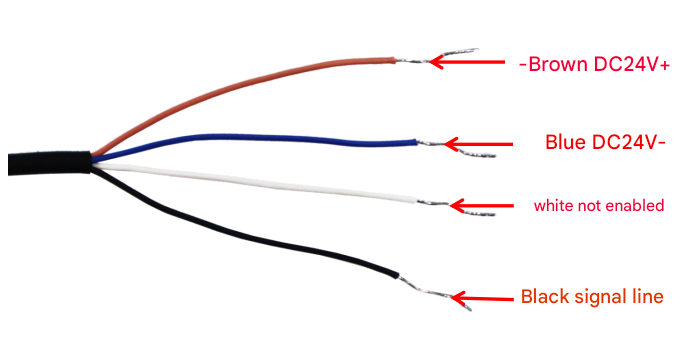

Wiring Instructions

| Brown Line | DC24V+ |

| Blue Line | DC24V- |

| White Line | Not enabled |

| Black Line | Signal line |

| Order Model | Perce91035-B1 |

| Reflector diameter/mm | 30 |

| Focusing lens diameter/mm | 25 |

| Supported focal length/mm | 50.8 |

| Overall dimensions/mm | W312*H359*D159 |

| Weight kg | 3.5 |

Product Information

Dual-axis rotating laser head

Product accessories

D3 Copper Mouth

94005 Focusing lens

94006 Reflective lens

94011 Quick Connector

94009-B Water Cooling Assembly

Reviews

There are no reviews yet.