Ruida knife cutting control system

TROCEN knife cutting control system

Kinco knife cutting control system

Ruida knife cutting control system

RDD6584G Functional Description:

- High-response tool direction following control, multiple tool processing methods are optional

- Integrated vibration knife, circular knife, milling cutter, pressure wheel, circular punching, V-shaped special punching, brush processing, red light positioning and multiple processing methods

- Support single XY axis processing, dual XY axis asynchronous processing, dual-head mutual shift processing

- Optional support for MARK point visual positioning cutting, large-format panoramic visual cutting, projection cutting, etc.

| Name | Specification |

| Model | Ordinary model |

| Axis | 8 |

| Input and out put | 32/28 |

| Communication interface | Ethernet,USB and WIFI(optional) |

| Panel | 7 touch screen,support parameter modification, static preview and dynamic display of graphics |

| Tool | vibration knife, round knife, milling cutter, press wheel, round punching, V-shaped punching, brush processing, red light positioning |

| Feeding | Support X/Y/U axis feeding independently or Y and U axes feeding synchronously |

| Camera | None |

| Light source system | None |

| Cutting function | Ordinary cutting |

| Installment encryption | Support |

| Onboard clock | Support |

| Firmware upgrade | Remote upgrade of panel and mainboard program |

| Software | VCutWorks |

| Operating system | Win7, Win8, Win10, 32-bit or 64-bit |

| Language | 15 languages including simplified Chinese, traditional Chinese, English, French, Russian, Portuguese, Turkish, German, Spanish, Vietnamese, Korean, Italian, Japanese, Indonesian and Polish |

| Size | Panel: L203.5mm*W149.5mm*H39mm Mainboard: L212mm*W136mm*H33mm |

| Accessories | Wireless handheld box, RD-APP and RD-WIFI |

Optional feature of RDD6584G

Wireless controller

Mobile APP

Automatic typesetting

RD BOX

Veutllork software part function

. Plug-in (AUTOCAD, coreDRAW)

. Import (ai, plt, dxf, pdf, nc, cut), export (ai, plt, dxf). Overcut compensation (let go, positive and negative cutting, extension, separation overcut)

. Blade advance and lag blade tilt compensation. Blade radius compensation. Eccentricity compensation

Groove width compensation

. Groove 0.90.180.270 multi-angle compensation

Layered cutting

. Brush radius compensation. Pressure wheel weight compensation. Back cutting

. Real-time online mode (32 versions)

. Projection positioning File monitoring. Automatic typesetting Kanban program

Bitmap edge lifting

. Layer order optimization sorting

Software control adsorption

Log function

. File paging transfer (32 versions)

Countertop analysis

. Built-in 17 language switches (Simplified Chinese, Traditional Chinese, English, French, Russian, Portuguese, Turkish, German, Spanish, Vietnamese, Korean, Italian, Indonesian, Polish, Japanese, Arabic, Finnish

RDD6616U Functional Description

- High-response tool direction following control, multiple tool processing methods are optional

- Integrated vibration knife, circular knife, milling cutter, pressure wheel, circular punching, V-shaped special punching, brush processing, red light positioning and multiple processing methods

- Support single XY axis processing, dual XY axis asynchronous processing, dual-head mutual shift processing

- Optional support for MARK point visual positioning cutting, large-format panoramic visual cutting, projection cutting, etc.

Parameter

| Name | Specification |

| Model | Ordinary double track model |

| Axis | 16 |

| Input and output | 43/43 |

| Communication interface | Ethernet, USB and WIFI (optional) |

| Panel | 7” touch screen, support parameter modification, static preview and dynamic display of graphics |

| Tool | vibration knife, round knife, milling cutter, press wheel, round punching, V-shaped punching, brush processing, red light positioning |

| Feeding | Support X/Y/U axis feeding independently or Y and U axes feeding synchronously;repeated multi-template feeding |

| Camera | None |

| Light source system | None |

| Cutting function | Double coordinate system asynchronous cutting |

| Installment encryption | Support |

| Onboard clock | Support |

| Firmware upgrade | Remote upgrade of panel and mainboard program |

| Software | VCutWorks |

| Operating system | Win7, Win8, Win10, 32-bit or 64-bit |

| Language | 15 languages including simplified Chinese, traditional Chinese, English, French, Russian, Portuguese, Turkish, German, Spanish, Vietnamese, Korean, Italian, Japanese, Indonesian and Polish |

| Size | Panel:L199mm*W145mm*H39.1mm Mainboard: L240mm*W151.5mm*H33.5mm |

| Accessories | Wireless handheld box, RD-APP and RD-WIFI |

RDD6584V-NET

- High-response tool direction following control, multiple tool processing methods are optional

- Integrated vibration knife, circular knife, milling cutter, pressure wheel, circular punching, V-shaped special punching, brush processing, red light positioning and multiple processing methods

- Support single XY axis processing, dual XY axis asynchronous processing, dual-head mutual shift processing

- Optional support for MARK point visual positioning cutting, large-format panoramic visual cutting, projection cutting, etc.

| Name | Specification |

| Model | Mark point vision positioning cutting model |

| Axis | 8 |

| Input and output | 32/28 |

| Communication interface | Ethernet, USB and WIFI (optional) |

| Panel | 7” touch screen, support parameter modification, static preview and dynamic display of graphics |

| Tool | vibration knife, round knife, milling cutter, press wheel, round punching, V-shaped punching, brush processing, red light positioning |

| Feeding | Support X/Y/U axis feeding independently or Y and U axes feeding synchronously |

| Camera | Network interface camera, 1.3 and 5 megapixels are available |

| Light source system | Red and white light source are available |

| Cutting function | Mark point vision positioning cutting |

| Installment encryption | Support |

| Onboard clock | Support |

| Firmware upgrade | Remote upgrade of panel and mainboard program |

| Software | VCutWorks |

| Operating system | Win7, Win8, Win10, 32-bit or 64-bit |

| Language | 15 languages including simplified Chinese, traditional Chinese, English, French, Russian, Portuguese, Turkish, German, Spanish, Vietnamese, Korean, Italian, Japanese, Indonesian and Polish |

| Size | Panel: L203.5mm*W149.5mm*H39mm Mainboard: L212mm*W136mm*H33mm |

| Accessories | Wireless handheld box, RD-APP and RD-WIFI |

RDD6616U-DFM

- High response tool direction follow control, multiple tool processing methods are available

- Integration of vibration knife, round knife, milling cutter, press wheel, round punching, V-shaped punching, brush processing, red light positioning and other processing methods

- Support single XY axis processing, double XY axes asynchronous processing and double tool heads synchronous processing

- Support Mark point positioning cutting, large-format panoramic visual cutting and projection cutting

| Name | Specification |

| Model | Panoramic large vision double track model |

| Axis | 16 |

| Input and output | 43/43 |

| Communication interface | Ethernet, USB and WIFI (optional) |

| Panel | 7” touch screen, support parameter modification, static preview and dynamic display of graphics |

| Tool | vibration knife, round knife, milling cutter, press wheel, round punching, V-shaped punching, brush processing, red light positioning |

| Feeding | Support X/Y/U axis feeding independently or Y and U axes feeding synchronously;repeated multi-template feeding |

| Camera | 2400W high resolution SLR camera |

| Light source system | None |

| Cutting function | Double coordinate system large vision contour recognition cutting |

| Installment encryption | Support |

| Onboard clock | Support |

| Firmware upgrade | Remote upgrade of panel and mainboard program |

| Software | VCutWorks |

| Operating system | Win7, Win8, Win10, 32-bit or 64-bit |

| Language | 15 languages including simplified Chinese, traditional Chinese, English, French, Russian, Portuguese, Turkish, German, Spanish, Vietnamese, Korean, Italian, Japanese, Indonesian and Polish |

| Size | Panel:L199mm*W145mm*H39.1mm Mainboard: L240mm*W151.5mm*H33.5mm |

| Accessories | Wireless handheld box, RD-APP and RD-WIFI |

TROCEN Motion Control Systems

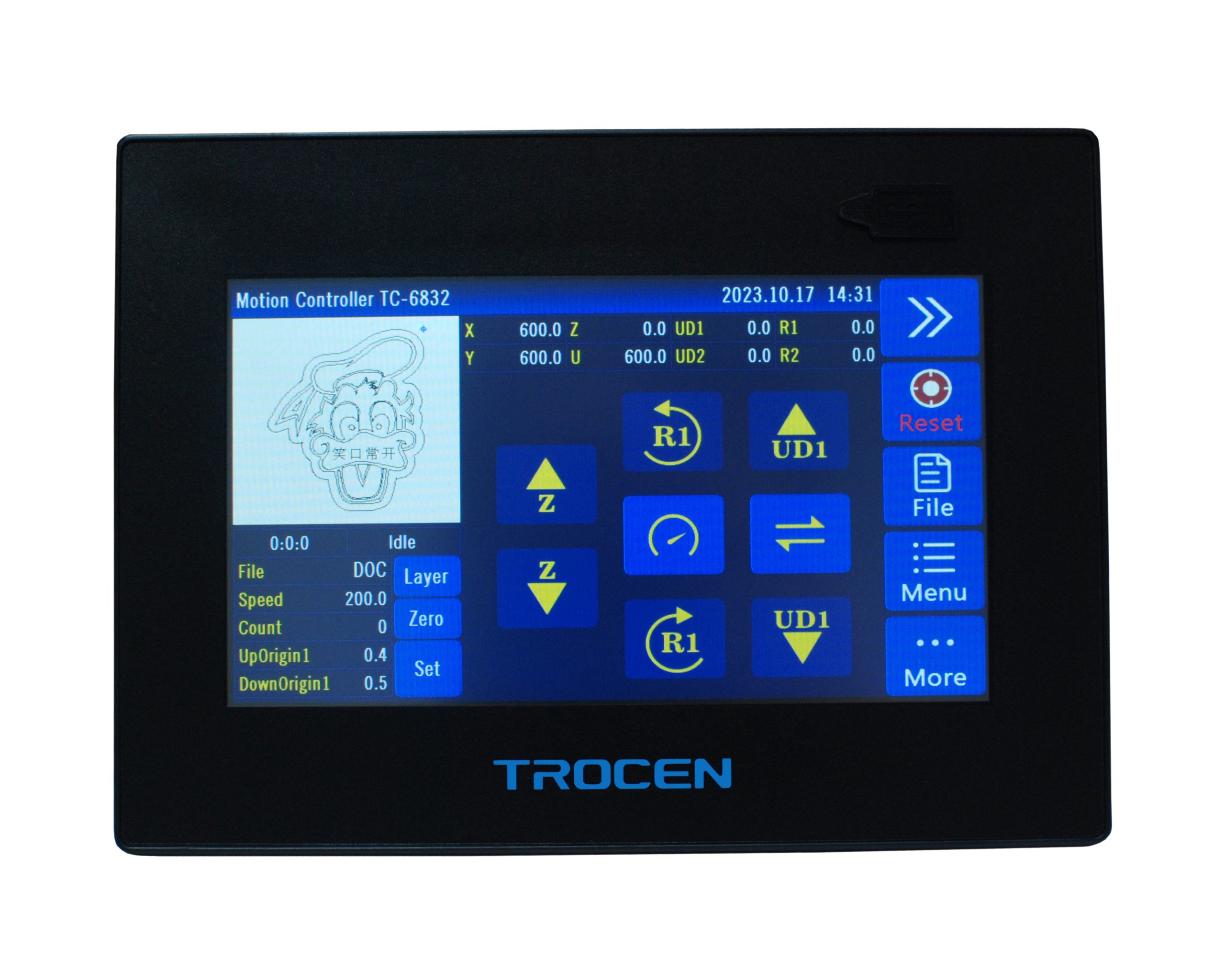

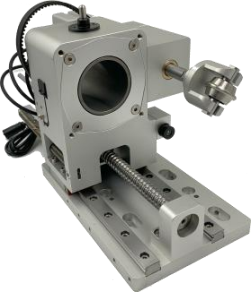

TC-6832 Montioncontroller

Product Introduction

TC - 6832 motion controller based on TC - 6828 pro the original function, for the touch screen, increase the spindle cutting indentation, V groove cutting, the press pulley, and other functions, support double head, three head at the same time, the main meet the technological requirements, higher requirements for equipment

The motion controller of the lower plane of this system has the following characteristics:

l high-speed DSP master control chip, faster operation speed, more advanced motion algorithm, better effect

l7 inch TFT LCD touch screen, more intuitive interface, easier operation

l all-optical coupling isolates external electromagnetic interference, making the system more stable and reliable

l support network, USB, U disk and other fast file reading and writing

l Support multi-working together, can double the efficiency

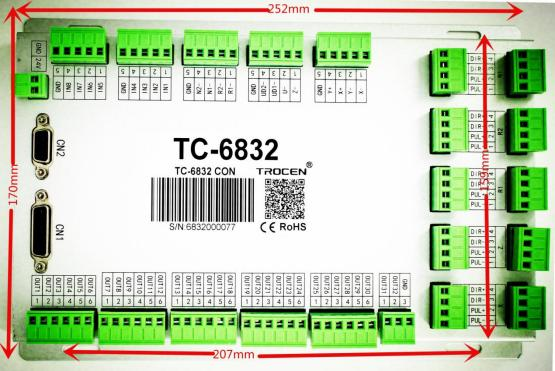

Baseplate appearance display and dimension drawing

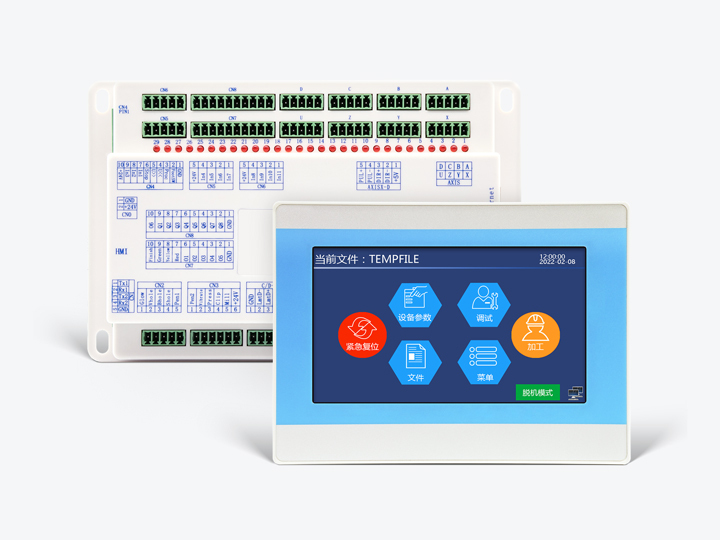

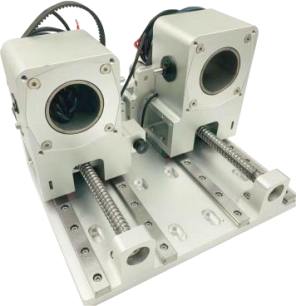

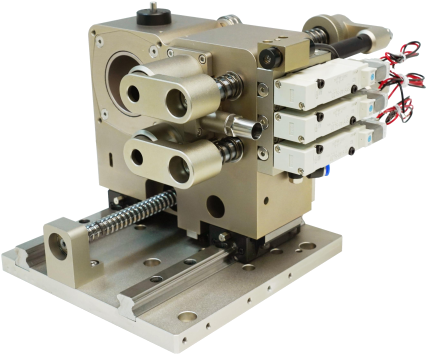

TC-7200t

TC7200t is a motion controller developed for dual-beam vibration knife cutting equipment, which perfectly integrates dual-head asynchronous technology, integrated punching and cutting and other cutting technologies. This product has a 7-inch large screen, rich functions such as feeding, brush, punching, V punching, etc., supports dual-head independent work, asynchronous cutting of different shapes of graphics, saving time and materials while doubling the equipment cutting efficiency.

Features:

High-speed DSP main control chip, faster computing speed;

Supports dual-head asynchronous control cutting

Supports integrated punching and cutting, high precision and fast speed;

Intelligent typesetting function;

Supports automatic continuous feeding;

Supports seamless splicing function;

Supports multiple communication methods, U disk communication, network communication or USB communication;

Supports completely offline independent control, supports U disk upgrade system, and is more convenient for maintenance;

Supports power-off continuous cutting function.

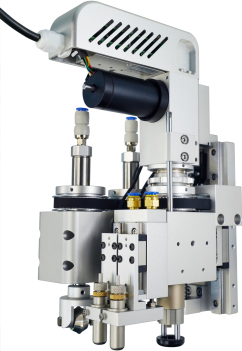

Suitable tools

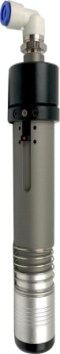

Vibrating knife:Cutting is achieved through high-frequency vibration of DC motor, which is suitable for medium-density materials. It can be matched with a variety of blades to adapt to the processing of materials of different thicknesses.

Knife Block:Install the tool

High power vibration knife:For materials with relatively high hardness and density.

Grooving Knife:

Suitable for cutting medium-hard materials, such as corrugated paper, to open grooves at different angles for easy folding. The groove cutters can be adjusted at different angles according to different needs.

Milling cutter: The material is processed by high-power spindle with high-speed rotation, mainly for non-metallic hard materials, such as acrylic

Pneumatic knife:A special pneumatic device is used to achieve high frequency amplitude, which is suitable for materials with high density and thickness, such as multi-layer fabrics, sponges, etc.

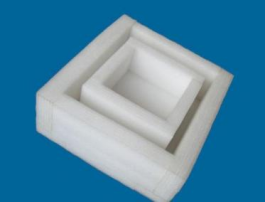

Servo Vibrating Knife:Through the 400W servo motor, high-frequency amplitude is achieved, which is suitable for medium-density materials and thick materials, such as EVA, pearl cotton, etc.

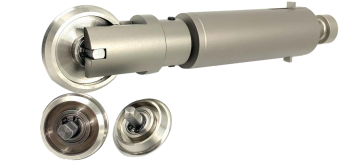

Round Knife:The material is cut by high-speed rotating blade, which is mainly suitable for cutting flexible materials such as cloth, leather, etc.

Pressure wheel:The material is creased by the creasing wheel. Different specifications of creasing wheels can be selected for materials of different thicknesses.

painting brush:Control the brush up and down to mark some materials

V-rush:Rotate the V-shaped direction, control the cylinder up and down, and process some materials with V-shaped cuts.

Round Punch:The circular punch tool rotates at high speed, controls the cylinder up and down, and performs hole opening work on some materials.

Coaxial tool holder:The pressure wheel/N punch/grooving tool is bound to the main tool holder and rotates with the main tool holder

Table collector:Collection table

Drag the knife:Blade vibration-free machining

Labeling Machine:Thermal paper printer cooperates with labeling device to print cutting information label

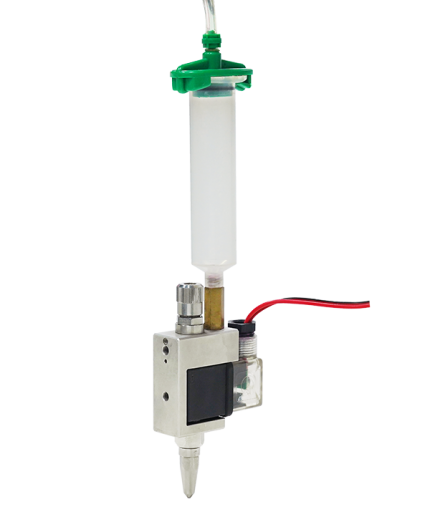

Inkjet valve:Control the high-frequency solenoid valve to spray the glue evenly along the drawing line

Half cutter:Automatically adjust the position of the knife tip to accurately position and cut the material to the right depth, so that only the surface layer and glue of the material are cut through without damaging the bottom paper.

Combined knife block:A variety of tools can rotate and rise and fall on the same axis, and the angle and tool depth can be controlled separately to meet various process requirements.

Double punch holder:Double punching binding knife holder rotates and rises together to control the punching depth separately

ink cartridge:Inkjet Printing

Industry Applications

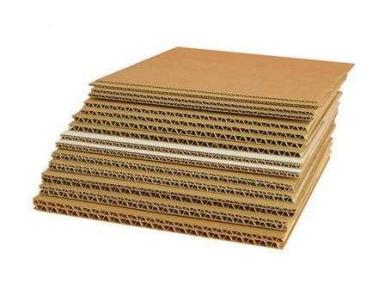

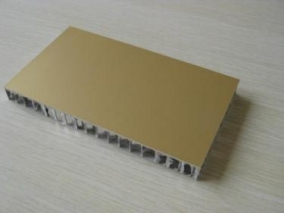

Packaging Industry

System selection: RDD6584G

Tool configuration: Vibrating cutter/drag cutter + pressure wheel; Vibrating cutter + slotting cutter; Servo vibrating cutter + milling cutter

Cutting materials: corrugated paper, honeycomb board, gray cardboard, white cardboard, EVA, composite materials, etc.

Processing method: You can first control the pressing wheel or slotting knife to indent or slot the material first, then control the vibration knife to cut, and complete the carton proofing; EVA material can choose servo vibration knife cutting and milling cutter milling groove

Sofa Industry

System selection: RDD6584G

Tool configuration: circular knife + vibrating knife + V punch

Cutting materials: cloth, leather, etc.

Processing method: For materials that need notching, the software can separate the notches, give priority to controlling the punching tool to process the notches, and then control the circular knife cutting. It can also optimize the notches and directly use the circular knife for processing, support feeding, over-width cutting, etc.

Automotive interior industry

System selection: RDD6584G

Tool configuration: Vibrating knife + circular knife

Cutting materials: foot pads, seat covers, wire loops, artificial leather, carbon fiber, sponge composite, etc.

Processing method: Software optimization can be used to increase the speed without lifting the tool

Advertising Industry

System selection: RDD6584V-NET

Tool configuration: Vibrating cutter + drag cutter + half cutter + high-power vibrating cutter + milling cutter

Cutting materials: KT board, PVC board, acrylic, adhesive, sticker, etc.

Processing method: Use small visual mark points to locate the cutting, and choose different tools for different materials.

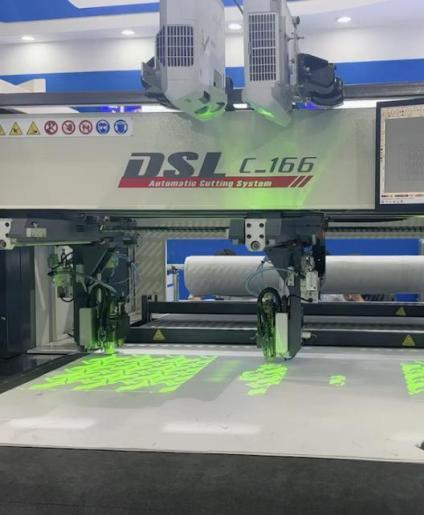

Digital Printing

System options: RDD6584G-DFM,RDD6616US-DFM

Tool configuration: Vibrating knife + circular knife

Cutting materials: printed fabrics, leather, etc.

Processing method: Use large-scale visual positioning cutting to automatically extract material contours

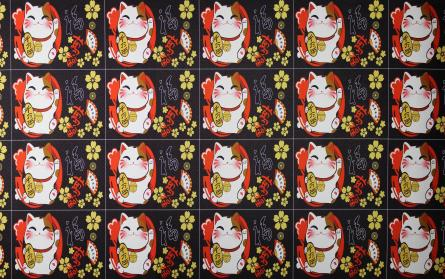

Carpet Industry

System options: RDD6584G-DFM,RDD6584G-DFM-DCAMERA

Tool configuration: Vibrating knife + circular knife

Cutting materials: printed carpet, diatom mud

Processing method: Using large visual positioning cutting, the same rectangular carpet can be cut in the same line, or cut by the edge separately. The machine format is large and can be equipped with dual cameras.

Soft glass industry

System selection: RDD6584G

Tool configuration: Vibrating knife + slotting knife

Cutting material: soft glass

Processing method: First control the groove cutter to draw a slope in one direction, and then use the vibration cutter to process. After processing, the cutting edge of the material has a half slope effect.

Clothing Industry

System options: RDD6584G, RDD6584G-PJ

Tool configuration: vibration knife + circular knife + brush + glue spray head + inkjet

Cutting material: Clothing fabric

Processing method: projection positioning processing, can use brush/jet head/inkjet printing to make marks, can connect all CAD clothing software DXF, AI, PIT files, manual alignment and layout

Photovoltaic industry

System selection: RDD6584G-DFM

Tool configuration: Vibrating knife + circular knife

Cutting material: Photovoltaic panels

Processing method: large visual positioning processing, precise trimming of photovoltaic panels, automatic docking production line

Shoe material industry

System options: RDD6584G, RDD6616US

Tool configuration: pneumatic knife + double punch tool holder + four punch tool holder

Cutting material: genuine leather, TPU

Processing method: Avoid defects in leather materials, use projection to assist positioning processing; TPU materials can be cut in multiple layers at the same time, projected and sliced, convenient for picking up materials, and double cantilever/double beam to improve processing efficiency

Curtain industry

System selection: RDD6584G

Tool configuration: round knife + labeling machine

Cutting material: curtain fabric

Processing method: The software first performs labeling control, prints out different information and sticks it on the cut piece, and then cuts it with a circular knife

Sound-absorbing board industry

System selection: RDD6584G

Tool configuration: Vibrating knife + slotting knife

Cutting material: Acoustic panel

Processing method: Use a slotting knife to cut slots with different shapes and patterns, and then use a vibrating knife to cut

Gasket industry

System selection: RDD6584G

Cutting material: gasket

Processing method: pneumatic knife cutting, automatic optimization path, from inside to outside, small circle speed limit and other processes to ensure cutting accuracy

Cutting material display

Self-adhesive advertising paper

Printed fabrics

Printed carpet

Soft Glass

Wire loop

Fur

Artificial leather

EVA

sponge

KT Board

PVC board

Acrylic

Reflective film

Carbon Fiber

Floor mats

Leather

Fabric

Gasket

corrugated paper

Plastic corrugated paper

White cardboard

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Reviews

There are no reviews yet.