Factory testing items

Product testing of vibration cutting machine accessories usually involves quality control in multiple dimensions to ensure their performance, safety and durability.

The following are common test contents and classifications:

I. Basic performance testing

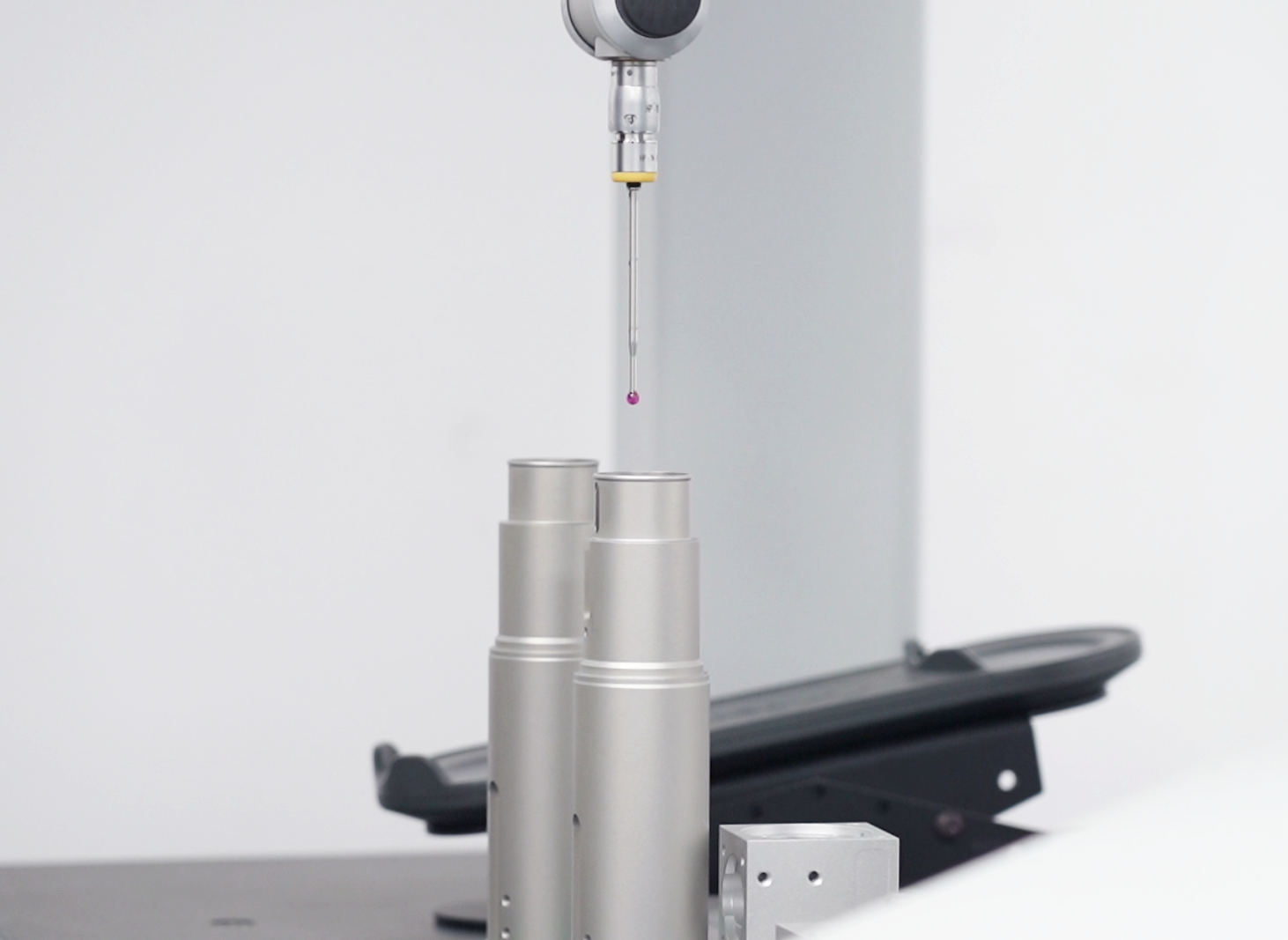

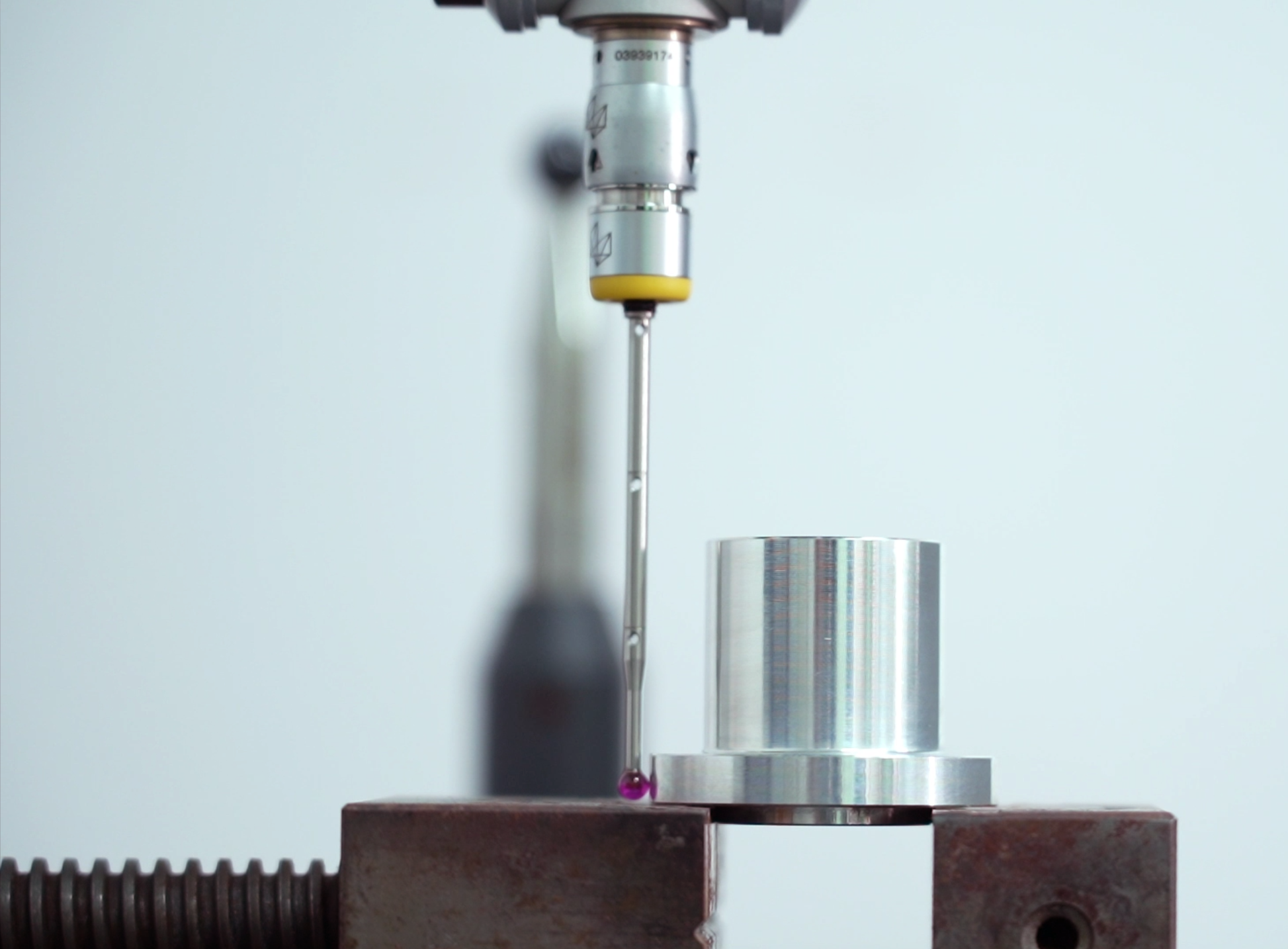

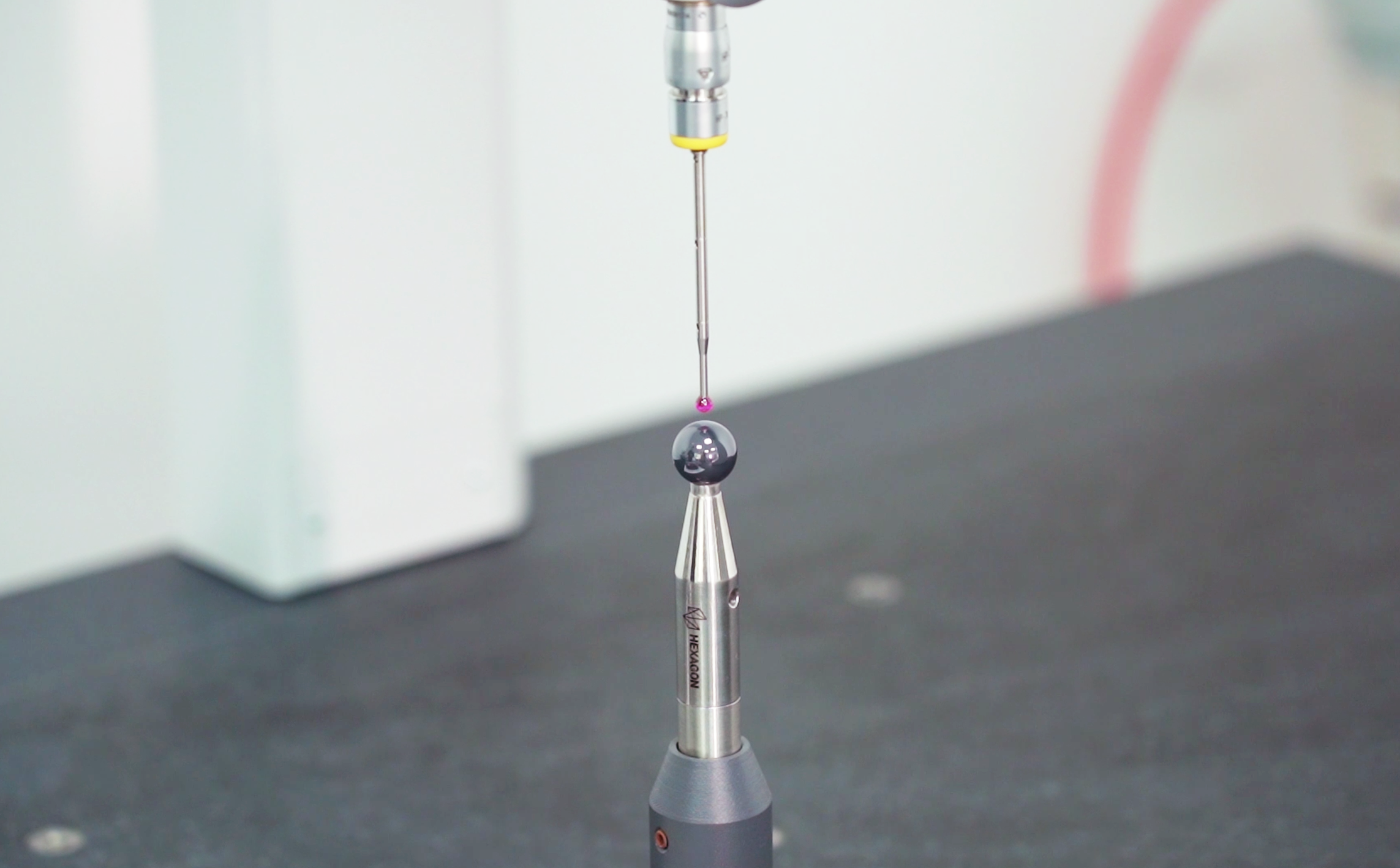

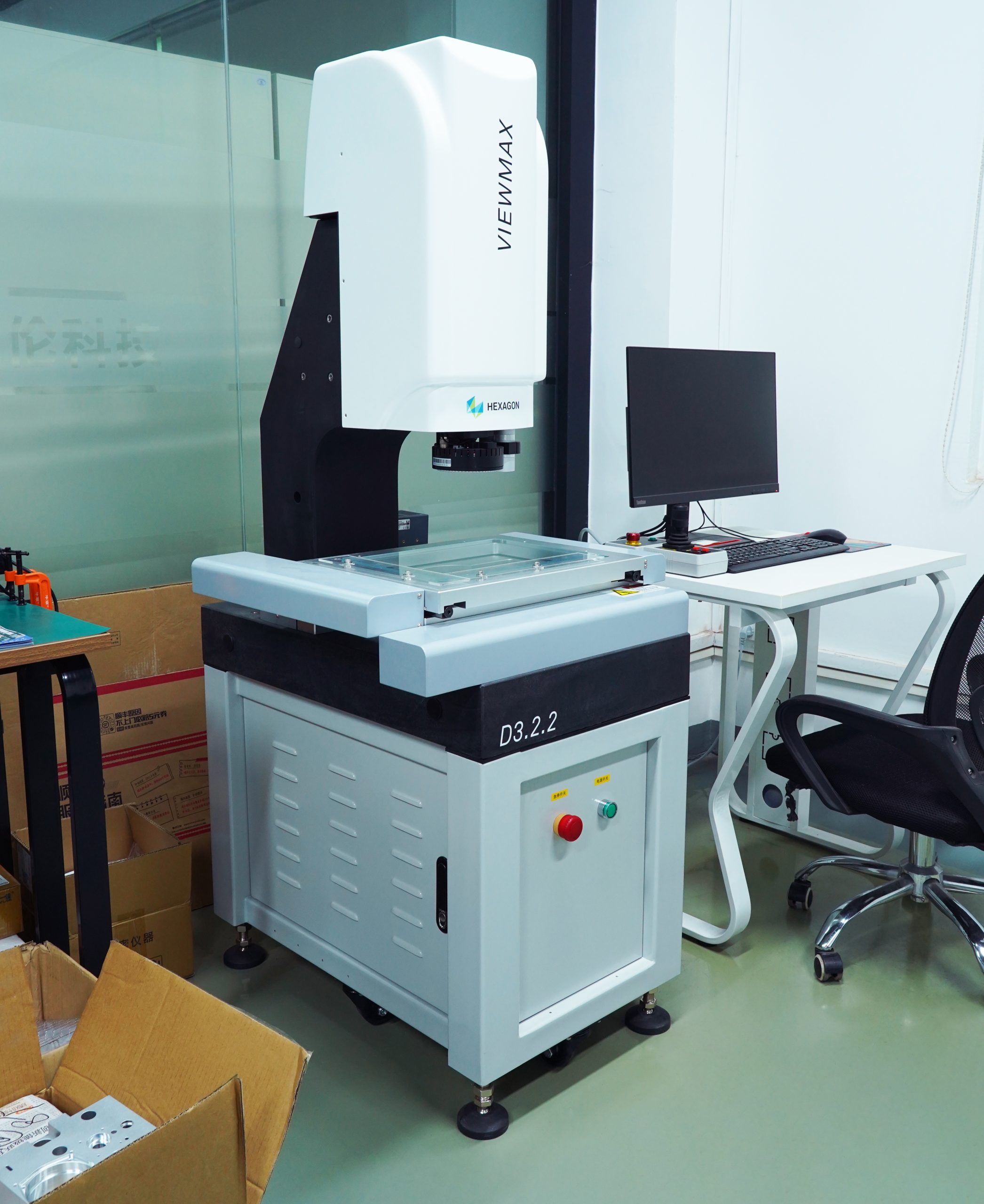

1. Dimensional accuracy testing

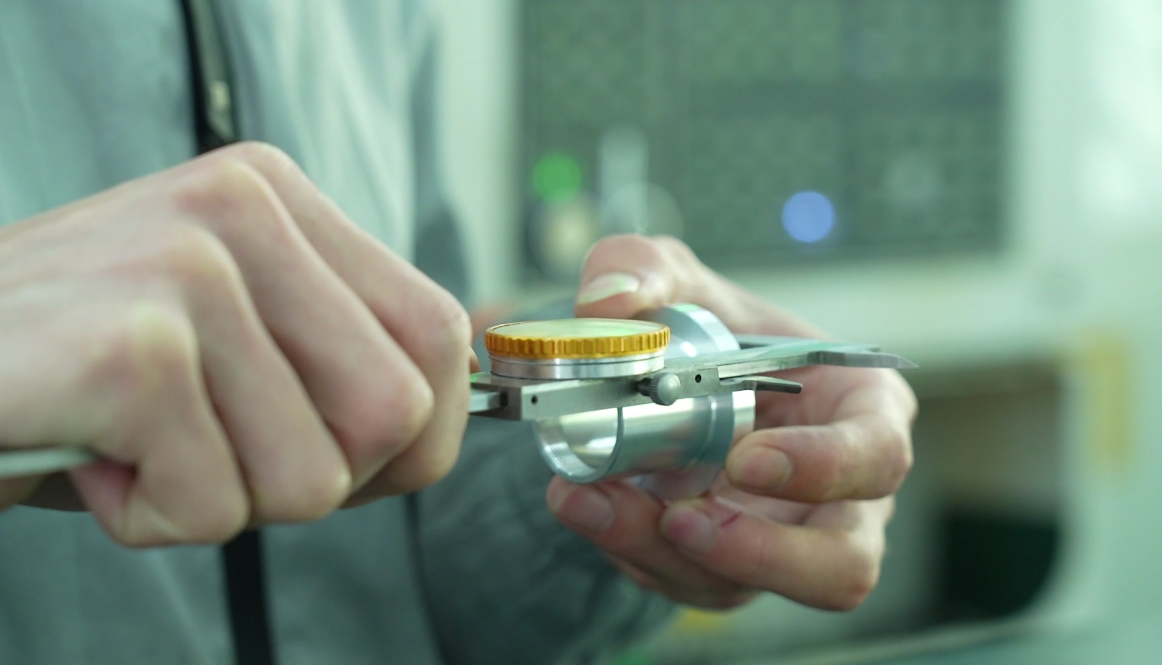

- Check whether the accessory dimensions (thickness, aperture, length, etc.) meet the requirements of the design drawings.

- Use tools such as calipers and three-coordinate measuring machines to verify the tolerance range.

2. Material performance testing

Material analysis: Use a spectrometer to verify the material composition (such as whether high carbon steel, alloy steel, etc. are used).

II. Functional and dynamic performance testing

III. Vibration characteristic test

Amplitude and frequency: Use a vibration sensor to detect whether the amplitude and frequency of the equipment are stable during operation.

Dynamic balancing test: Perform dynamic balancing calibration on rotating parts to avoid abnormal vibration caused by imbalance.

IV. Safety and reliability testing

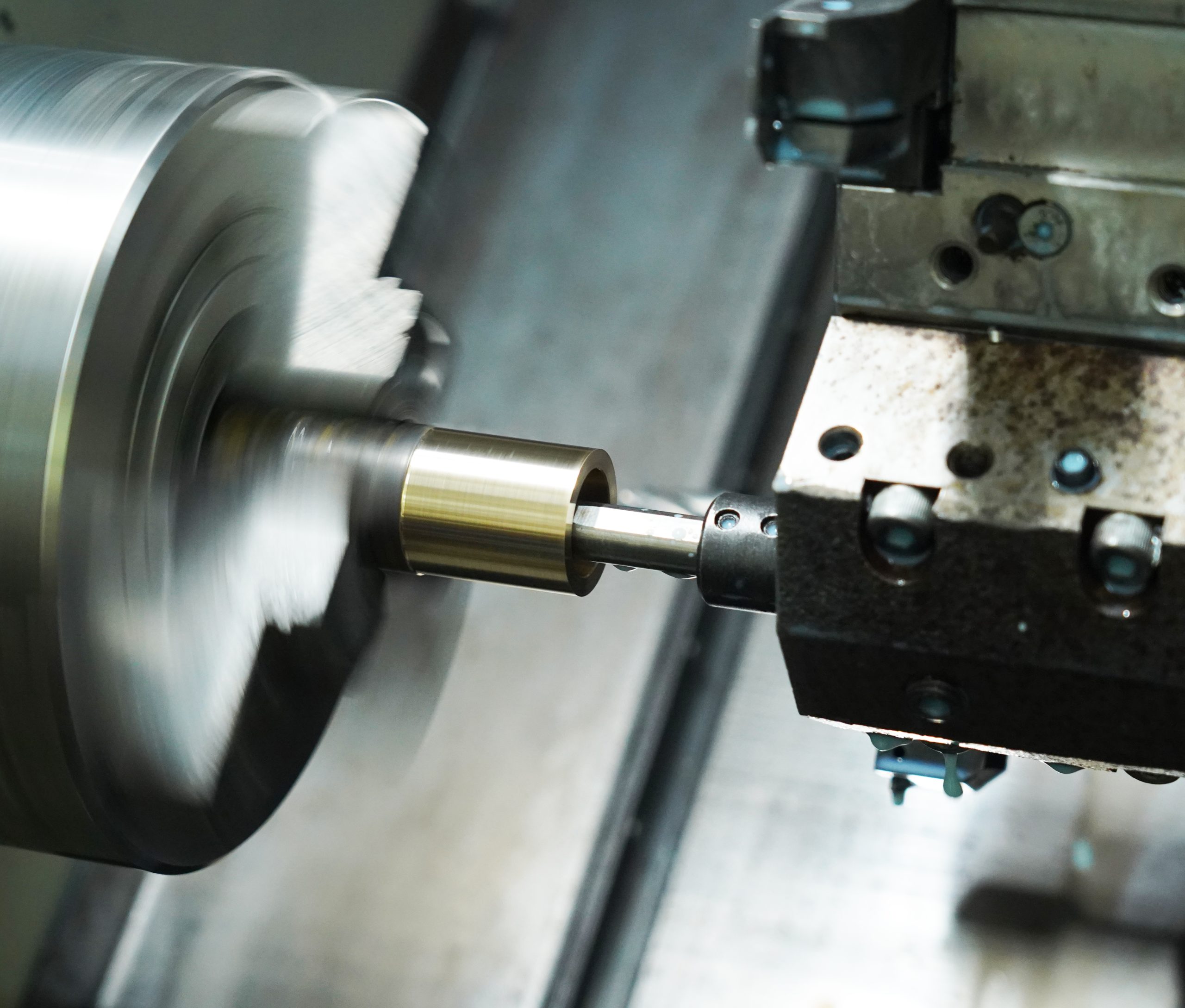

1. Load test

Operate under rated load and overload conditions to monitor whether the accessories are deformed, cracked or failed.

2. Fatigue life test

Simulate long-term continuous work (such as more than 24 hours) to observe the fatigue strength of key components.

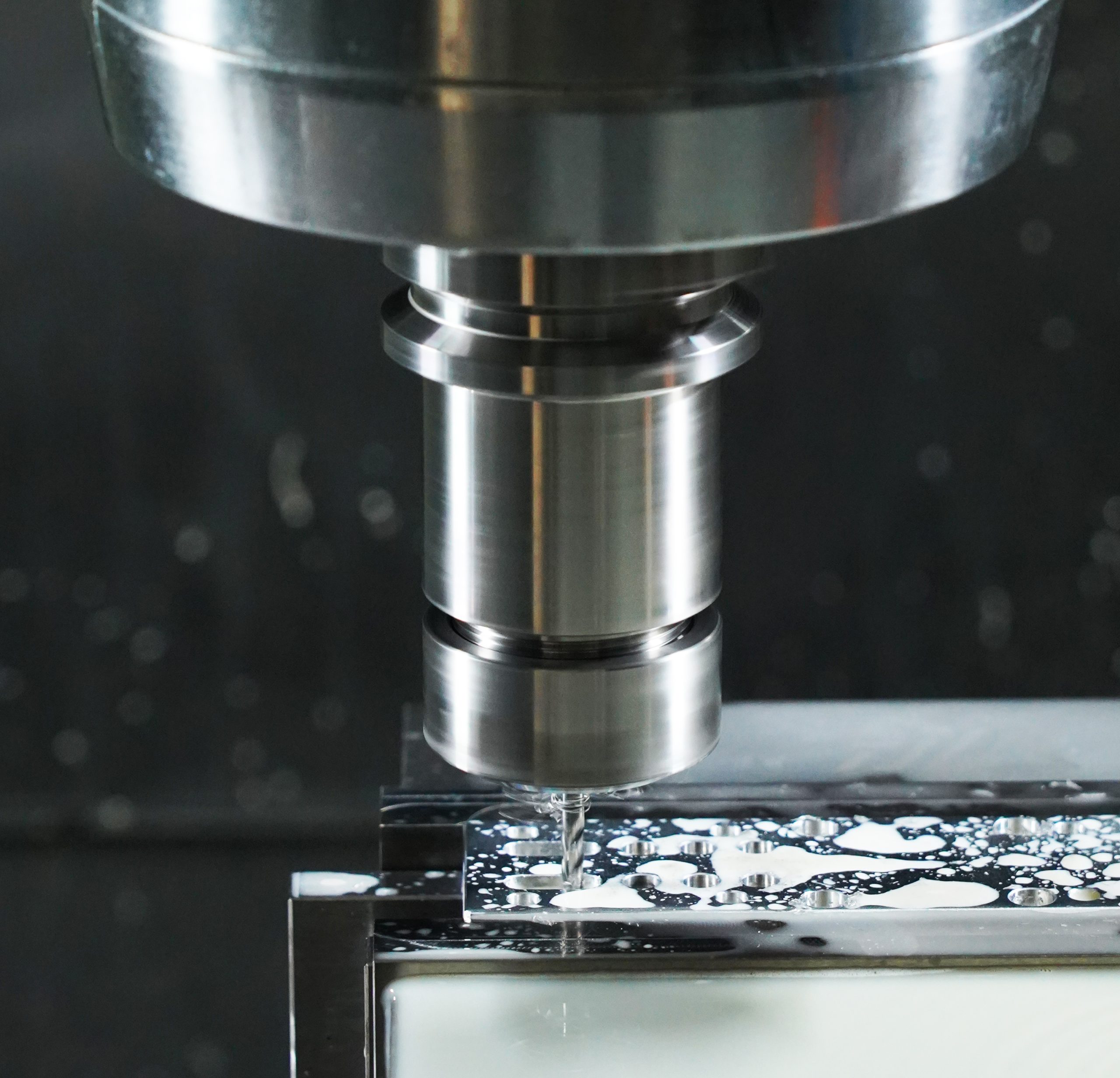

V. Assembly and compatibility test

1. Matching accuracy test

Verify the matching of accessories and host interfaces (such as mounting holes and thread matching).

Test the overall running smoothness after assembly to avoid interference or jamming.

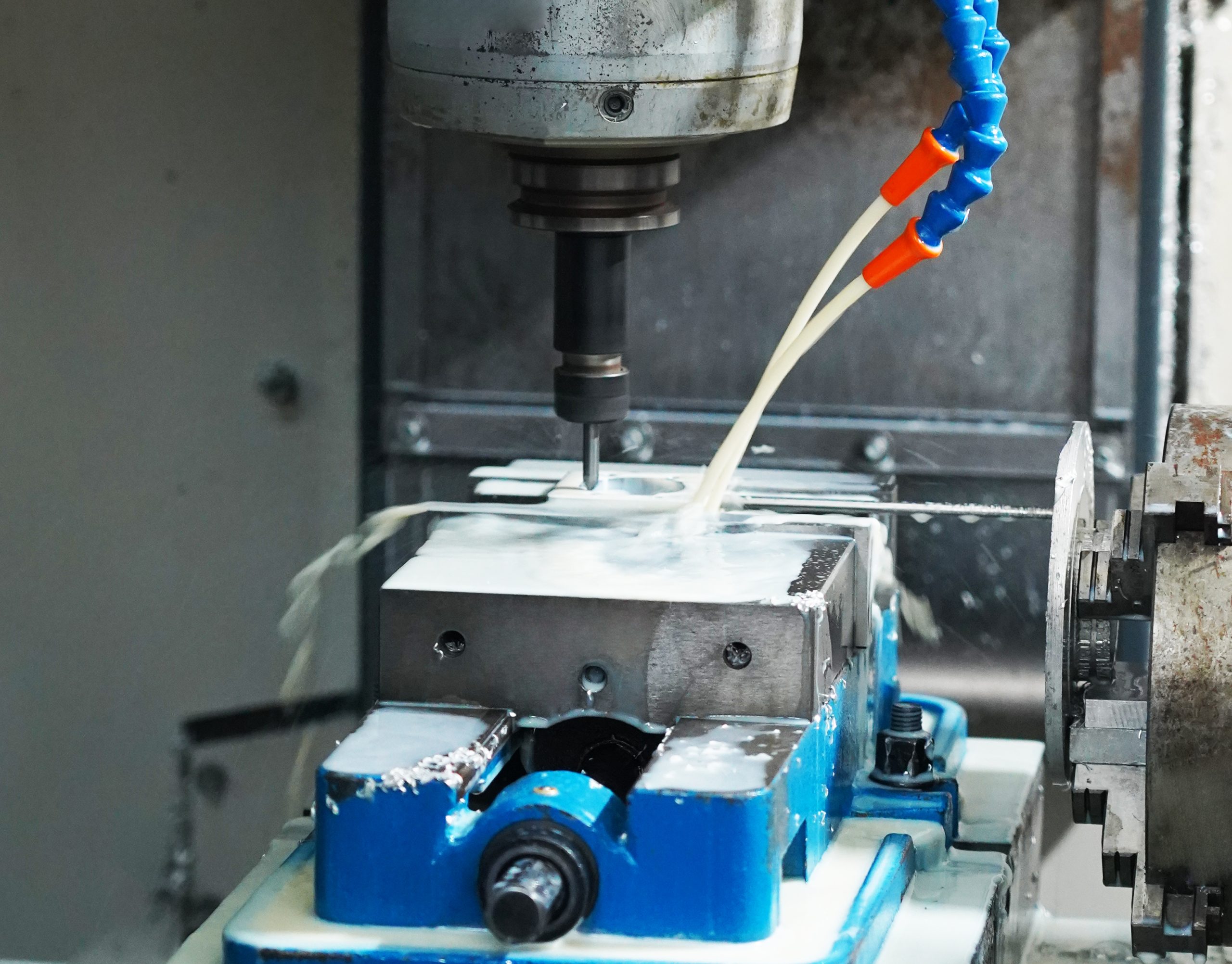

2. Sealing test

Pressure test the accessories of hydraulic or lubrication systems to ensure no leakage (such as oil seals and pipe joints).

VI. Appearance and packaging test

1. Visual inspection

Check whether there are cracks, burrs, rust or scratches on the surface.

Identification clarity (such as brand, model, production batch number).

2. Packaging test

Verify the reliability of shockproof packaging (drop test).

Check whether the accompanying documents (instructions, certificates of conformity) are complete.

Testing process recommendations

1. Incoming material inspection (raw materials/purchased parts) → process inspection (random inspection during processing) → factory final inspection (full function test).

2. Use automated testing equipment combined with manual re-inspection to improve efficiency and accuracy.

Through the above tests, the quality of vibration cutting machine accessories can be fully guaranteed, the equipment failure rate can be reduced and the service life can be extended.

Workshop

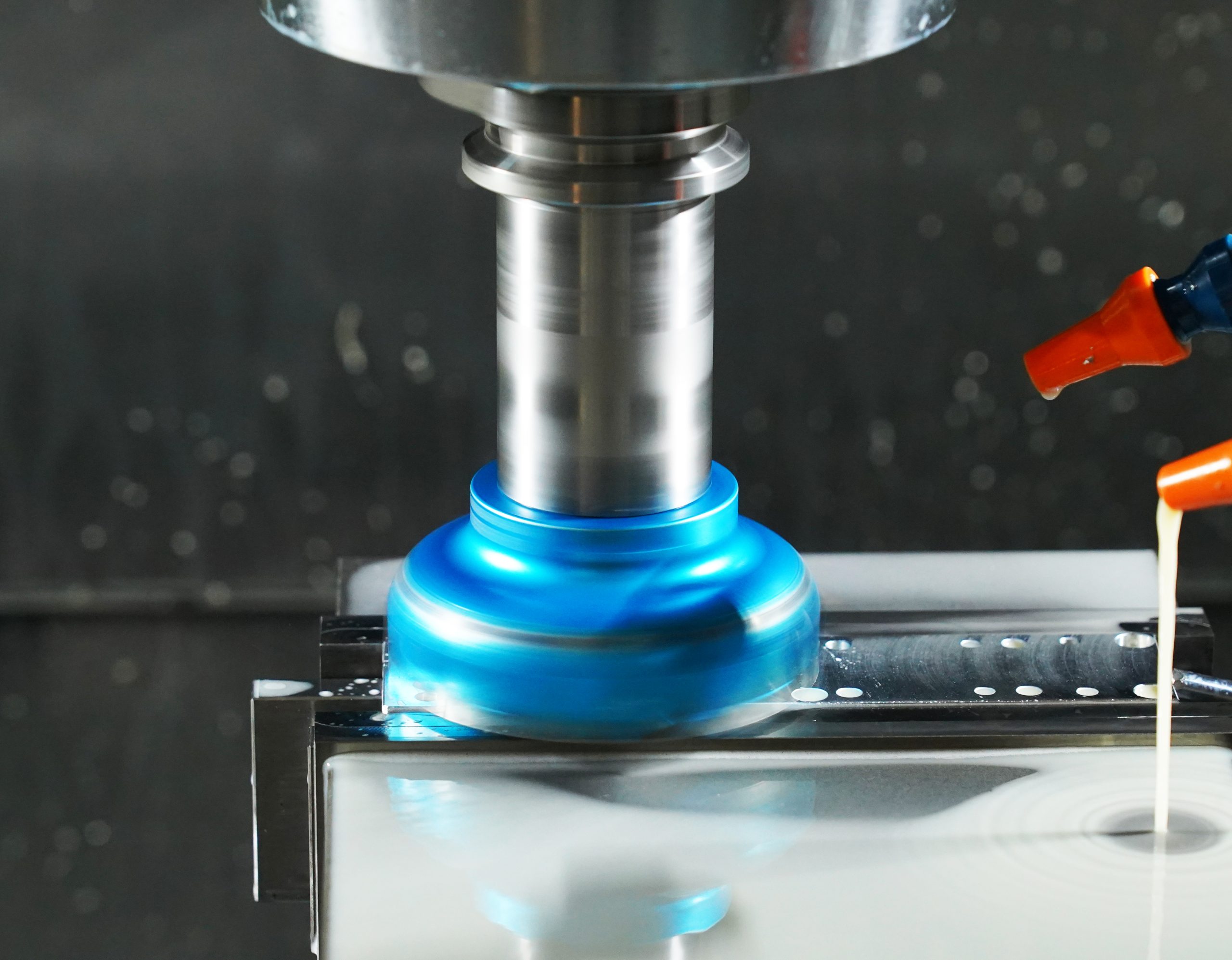

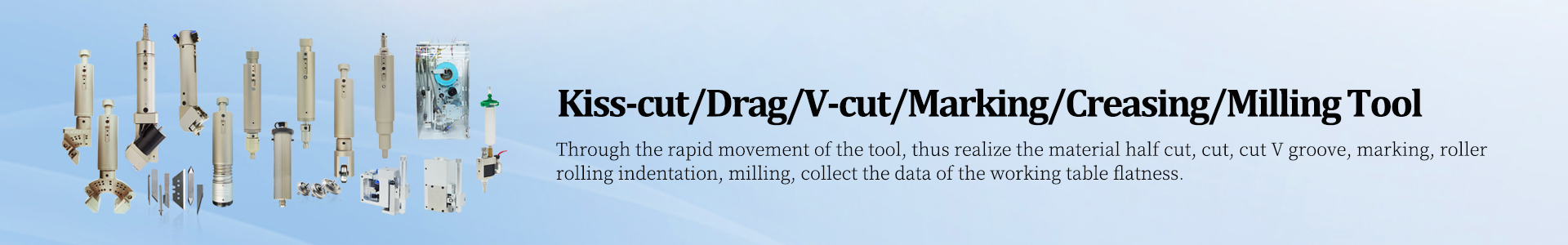

PERCE Precision Technology Co., Ltd. focuses on the research and development, production and sales of tool holders, tool heads, and mixed cutting laser heads. It has been recognized by relevant national departments in terms of research and development and innovation, and has entered the ranks of high-tech enterprises.

PERCE Precision Technology has its own R&D, production and sales teams, equipped with modern production, testing and assembly workshops, to achieve one-stop service of design, production and sales, and can quickly respond to market changes and solve customer needs in a timely manner.

The company has obtained many patents and has a rich variety of products: tool holders, vibrating knives, circular knives, pneumatic knives, drag knives, pressure wheels, bevel knives (grooving knives), V punches, circular punches, brushes, half-cut knives, table collectors, mixed cutting heads, non-metallic follow-up heads, etc., to achieve independent control of core technologies.