INTRODUCTION

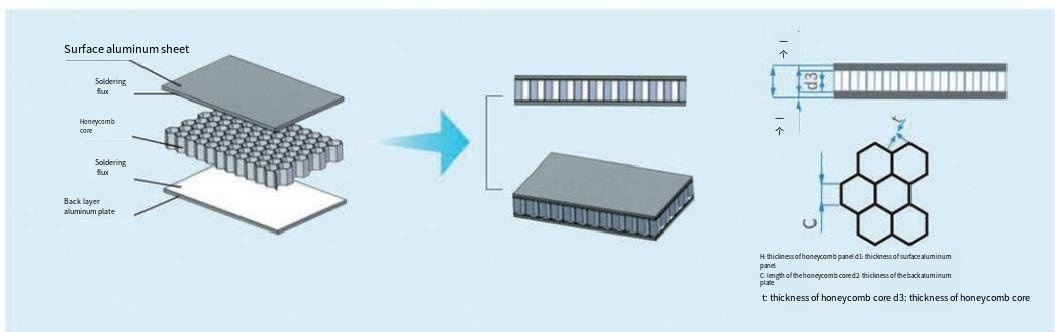

The aluminum alloy honeycomb platform is a new type of composite material made by welding the frame and gluing the panel and the honeycomb core through a series of processes. While fully integrating the advantages of high stability (strength) and flatness of the aluminum honeycomb, it forms a high-strength box with the welded frame and the aluminum plate on the bottom. It has excellent performance in terms of lightweight, mechanical properties (flat pressing, flat pulling, bending, side pressure, tensile shearing, roller peeling, etc.), and weather resistance.

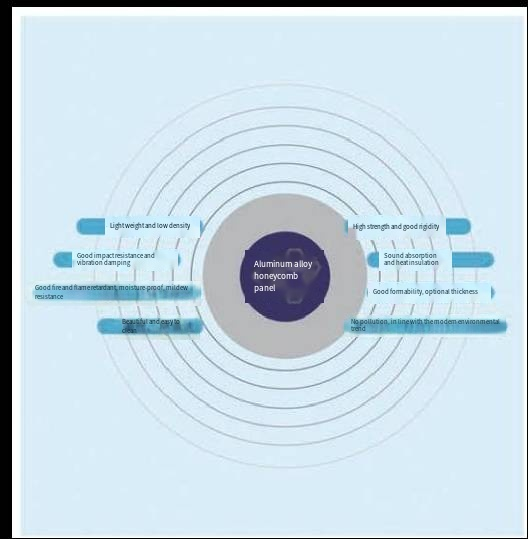

CHARACTERISTICS

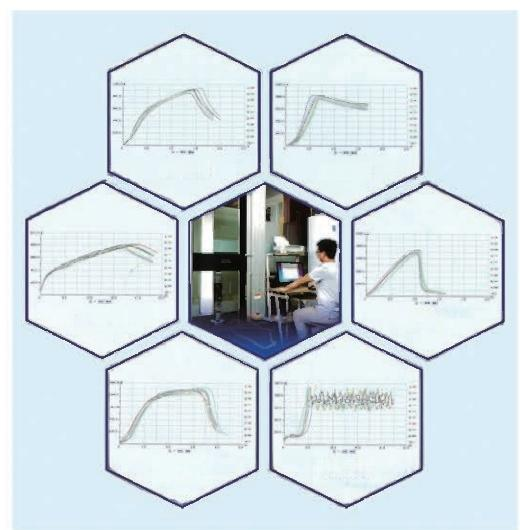

MECHANICALPROPERTIES

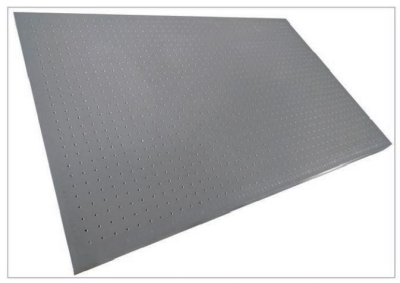

CUTTING MACHINE VOCUUM SUTION PLNEL

Suction platform parameters

Spot specifications(mm) | 2600*1700 (Maximum specification 2100*3300 without splicing) | Surface treatment | Natural color/hard anodized |

Adsorptionplatform thickness(mm) | 35/42.5 | Flatness(mm) | 0.10 to 0.30 |

Panel aperture(mm) | 1.5/1.8/2.0 | Panel thickness(mm) | 2 |

Panel diameter(mm) | 15/20/25/30 | Base plate thickness(mm) | 2 |

Panel material | 5 series aviation aluminum | Air intake aperture(mm) | Click on the picture |

Interface | Flange/Sheet Metal Cover | Operating temperature | <55℃ |

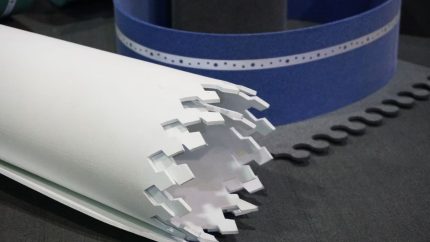

UV PRINTER VOCUUM SUTION PLNEL

Suction platform parameters

Spot specifications (mm) | 600*900/1300*2500/2000*3000 (Maximum size 2100*3300 without splicing) | Surface treatment | Hard anodizing |

Adsorption platform thickness (mm) | 24/35/42.5 | Flatness(mm) | 0.10-0.30 |

Panel aperture(mm) | 1.5/1.8/2.0 | Panel thickness (mm) | 2 |

Panel diameter (mm) | 15/20/25/30 | Bottom plate thickness (mm) | 2 |

Panel material | 5 series aviation aluminum | Air intake aperture (mm) | Click on the picture |

Interface | Flange/Sheet Metal Cover | Operating temperature | <55℃ |

TECHNICAI EXCHANGE

Q: What is the hard anodizing of the aluminum suction platform? What are the advantages and disadvantages?

A: Hard anodizing is a thick film anodizing method, which is a special anodizing surface treatment process for aluminum and aluminum alloys. This process generally produces an oxide film thickness of about 45 microns on the aluminum adsorption platform, with a hardness of about HV 400 to HV 600 (close to the surface hardness of stainless steel 304), with the advantages of scratch resistance, heat insulation, stability, and beauty.

Q: How can the flatness of the aluminum suction platform be improved? How to design the layout of the adjustment points?

A: In addition to the common adsorption function, the greatest value of the aluminum honeycomb platform is reflected in its flatness. The adsorption platform we provide, under natural conditions, generally has a flatness of less than 0.3 mm. In order to achieve the best equipment use effect, customers must design some installation fixing points or adjustment points. It is recommended that the distance between these points be controlled between 220mm and 400mm. After these adjustments, the entire adsorption platform can be adjusted to about 0.05mm to 0.15mm. If optimization or improvement is required, our engineers will assist in providing the best solution suggestions.

Q: How are the holes of the aluminum suction platform designed to have a stronger suction force?

A: There are many factors that determine the size of the suction force, including the structure, diameter, and spacing of the panel holes, the internal air duct design of the suction plate, the layout and size of the suction holes, etc. The suction design must also take into account other factors such as the structure, strength, and processing of the suction plate. Therefore, an excellent suction plate is a comprehensive consideration of the above factors, rather than being determined by one or two aspects.

Q: Is it necessary to do hard oxidation on the adsorption platform of the cutting machine industry?

A: Whether it is necessary depends on the positioning of the equipment manufacturer. From my personal understanding, if the cutting machine is a fixed table, for better equipment cost performance, there is no need to do hard oxidation; if it is a walking table and positioned at the high end, hard oxidation is still necessary, because the adsorption plate surface of the walking table will produce friction with the felt. If it is not hard-oxidized, the synchronization of the felt will be poor after a long time, and the positioning will not be so accurate; and the super wear resistance of the hard-oxidized surface can effectively avoid the occurrence of this problem, but hard oxidation requires a lot of cost, which requires the equipment manufacturer to weigh.

Q: If my customers print heavy materials such as marble or metal, does the table need special design?

A: Because the strength of the normal adsorption platform is mainly for most advertising materials, if it is a marble or metal printing table, special instructions are required, and the internal structure of the adsorption plate needs to be additionally strengthened.

Q: How long does it usually take to deliver your adsorption platform? Can it be faster?

A: Our company usually delivers adsorption platforms within 15 days. In order to better serve customers and meet the current market competition, we usually control the delivery time within 5 days for urgent orders, customized orders, sample orders, etc. from long-term cooperative customers. In special cases, it may be within 3 working days.

Q: What are your company's commitments to your product quality and service?

A: If you are not satisfied with the quality or service at any time, you can return it unconditionally.

Reviews

There are no reviews yet.