Drag knife-F can process PP paper, PP adhesive, reflective materials, car stickers, ABS plastic, thin plastic, rubber cloth, imitation leather, KT board, chevron paper, cardboard, soft glass and other materials.

The drag knife cuts the material through the rapid movement of the tool, allowing the material to be cut at the fastest processing speed, with high cost performance and low maintenance cost.

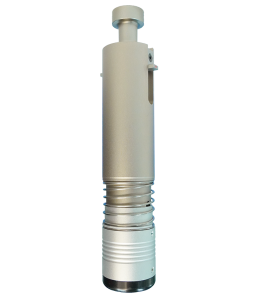

Component Description

Clip: used to lock the knife handle

Knife handle: drags the blade

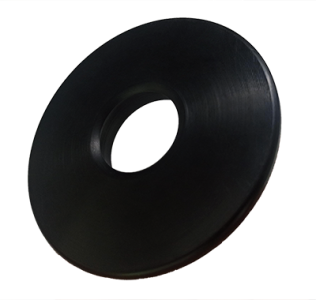

Knife head cap: used to press the material when cutting

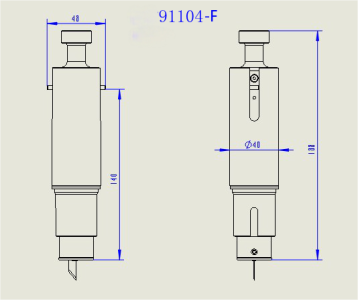

Installation dimensions

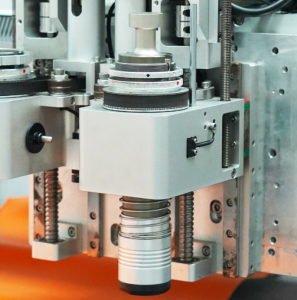

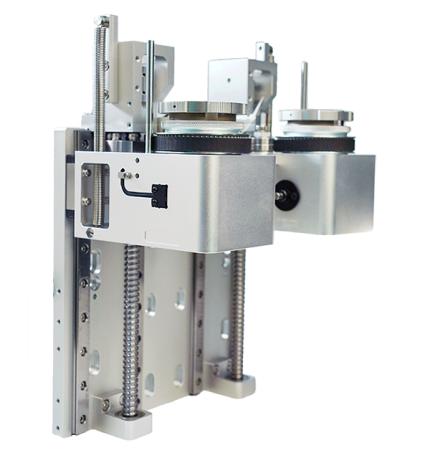

Installation diagram

Instructions for use and debugging

(1)Installation and removal of the cutter head cap

Align the guide rivet on the blade cap with the guide groove of the drag knife handle, press the blade cap into the handle with a little force, and when you hear a click, the blade cap is in place.

Check whether the blade cap barrel moves up and down smoothly.

When pulling out the blade cap, keep the blade cap and the handle in a straight line and pay attention to safety.

(2)Blade installation

Loosen the M4 top screw, insert the blade into the blade clamp (pay attention to the direction of the blade), and tighten the M4 top screw to complete the blade installation.

(3) Blade clamp removal

Method 1: Use a screwdriver to move the blade clamp back and forth until the blade clamp loosens and can be removed (recommended).

Method 2: First clamp the waste blade with a blade clamp, then clamp the blade clamp with pliers and pull it out.

Notice

- Non-professionals are not allowed to disassemble the blade

- Before each cutting, make sure the M4 top screw is locked to prevent the blade from slipping out.

Order Model

Product Parameters

| Order Model | Perce91104-F |

| Overall dimensions/mm | W48*H188*D40 |

| Weight kg/W | 0.4 |

Reviews

There are no reviews yet.