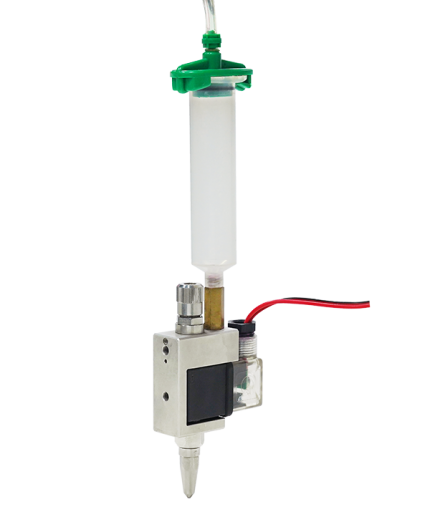

The pneumatic brush can draw various patterns and tool path motion trajectories on the cut material.

The basic principle of the pneumatic brush is to use compressed gas to drive the brush to contact the cut material, thereby drawing a given trajectory.

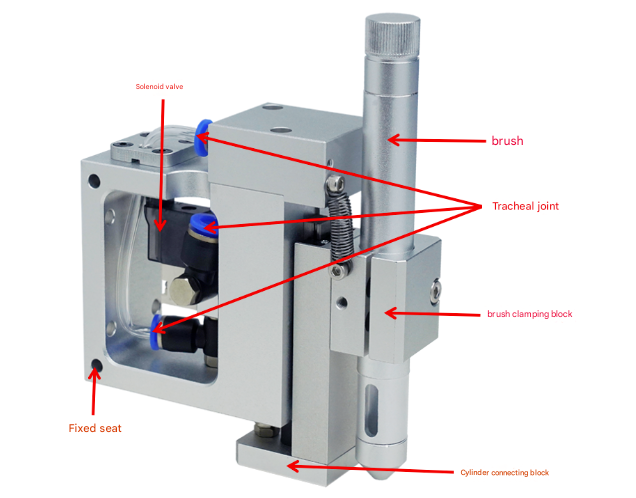

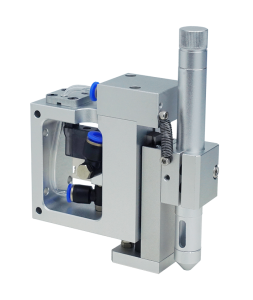

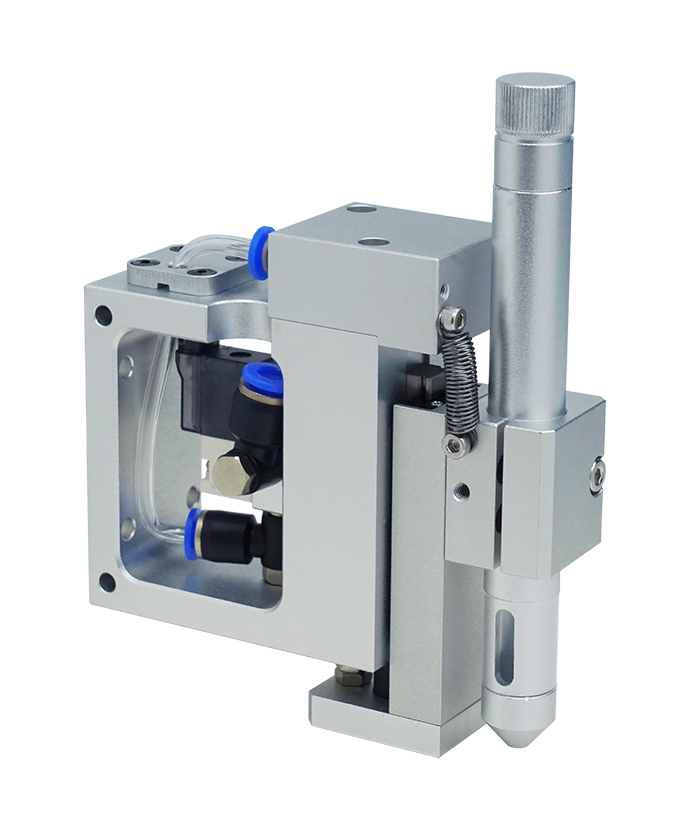

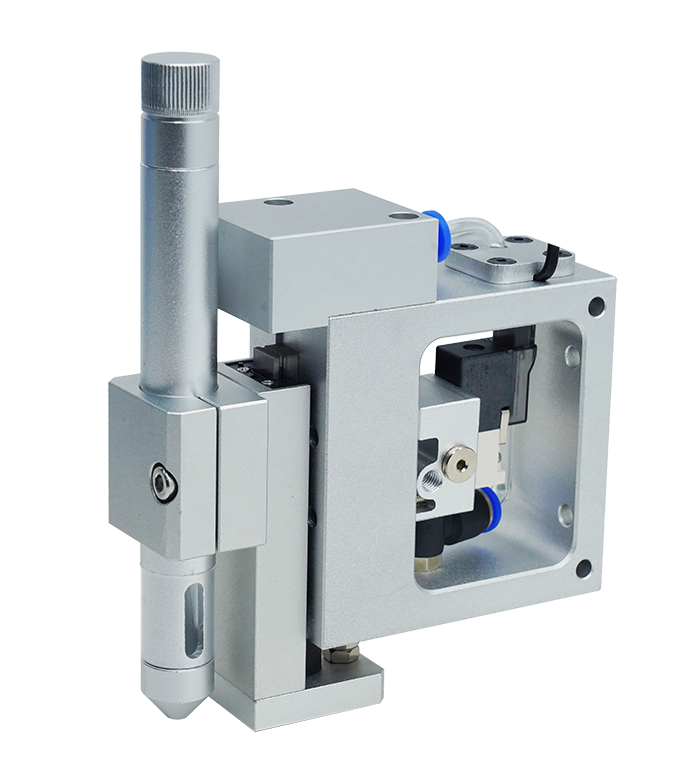

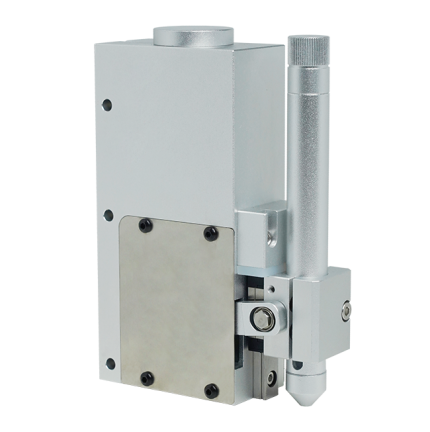

Component Description

Air pipe joint:air inlet

Fixed seat: connected to the machine tool

Solenoid valve: used for up and down movement reversal

Cylinder connecting block: connects the cylinder and the brush

Brush clamping block: used to tighten the brush

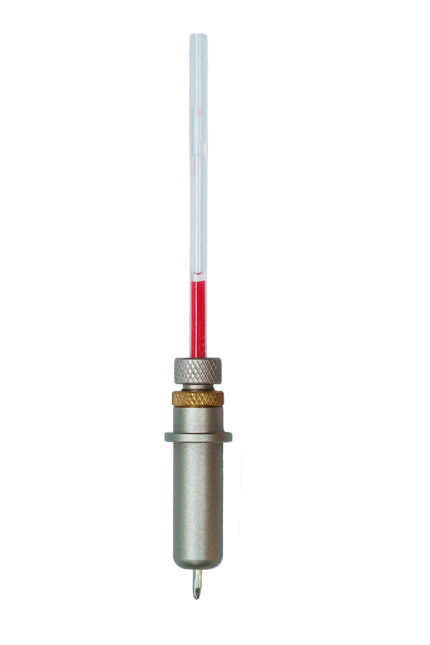

Brush: draw the pattern trajectory

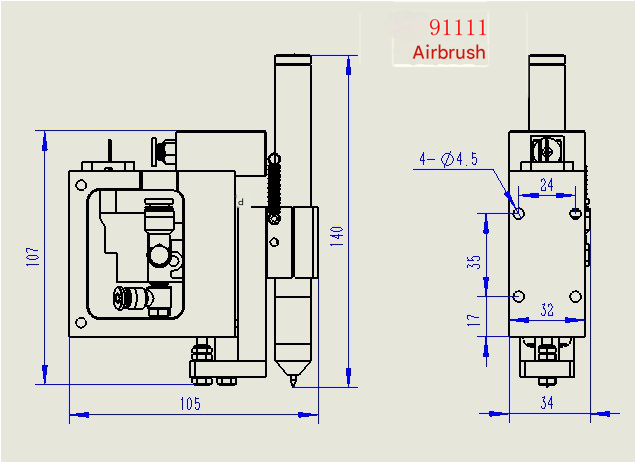

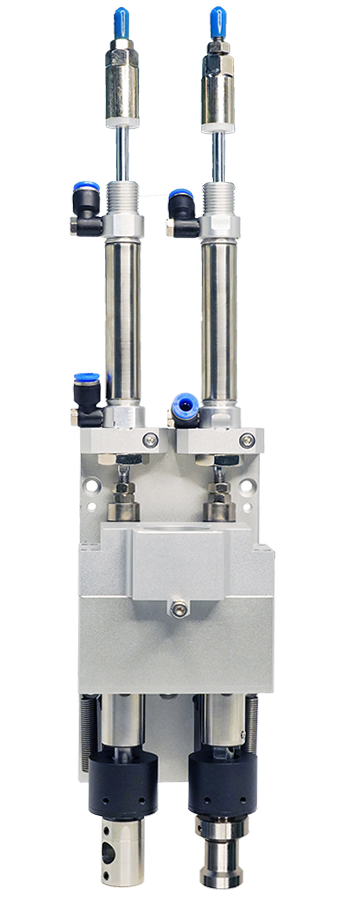

Installation Dimensions

Installation Diagram

Instructions for use and debugging

(1)Brush installation

Loosen the M4 screw, place the brush on the clamping block, adjust the brush to the appropriate position, and tighten the M4 tightening screw.

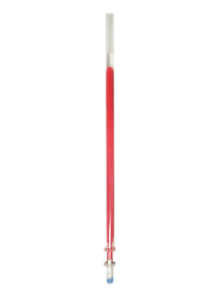

(2)Refill replacement

Twist out the cap from the pen holder, insert the refill, and tighten the cap to complete the refill replacement.

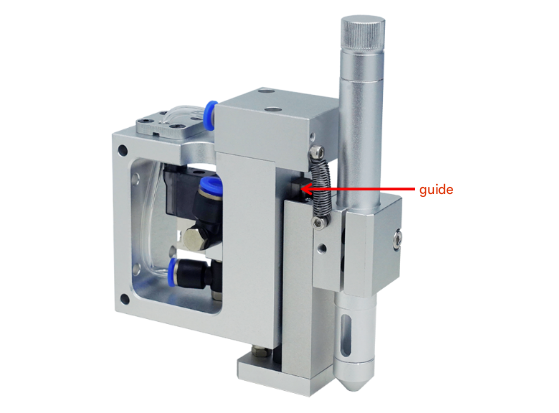

(3) Oiling and maintenance

Apply lubricating oil or grease to the guide rail to keep it sliding smoothly.

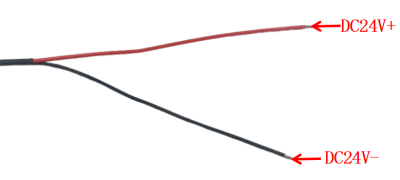

Wiring Instructions

Red Line:DC24V+

Black Line:DC24V-

Precautions

- Before powering on, make sure the wiring is correct

- Lubricate the rails in time to ensure the life of the brush

- The air pressure required to be connected is below 0.4Mpa

Product Parameters

| Order Model | Perce 91111 |

| Drive mode | pneumatic |

| Stroke/mm | 15 |

| Overall dimensions/mm | W34*H140*D105 |

| Weight kg | 0.5 |

Shipping Configuration

Perce 91111 Pneumatic Paintbrush

Perce 95028 Refill

Optional accessories

Perce 95027 Pen Holder

Perce 95028 Refill

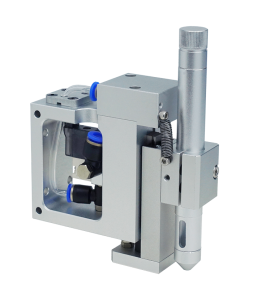

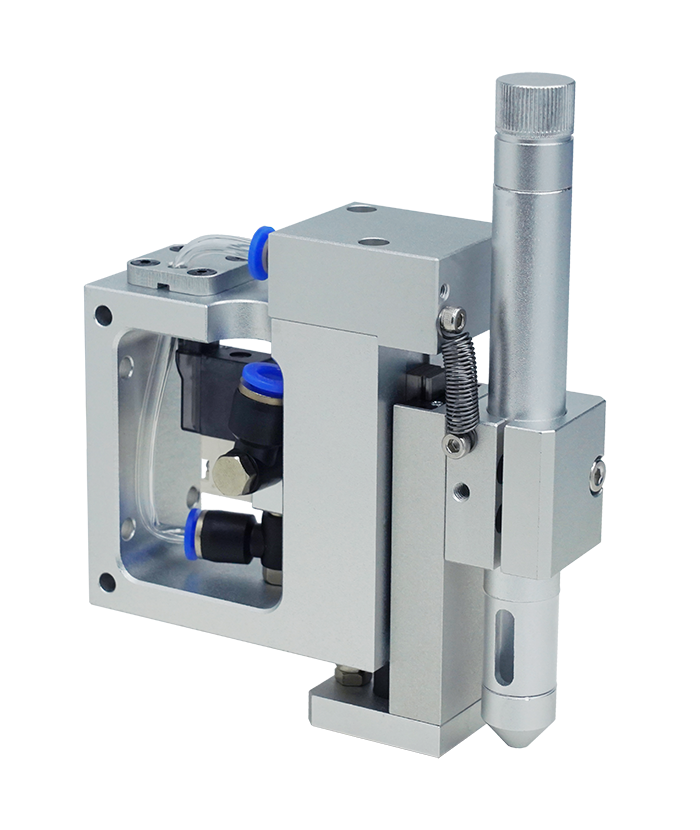

Multi-faceted appearance

Reviews

There are no reviews yet.