Overview

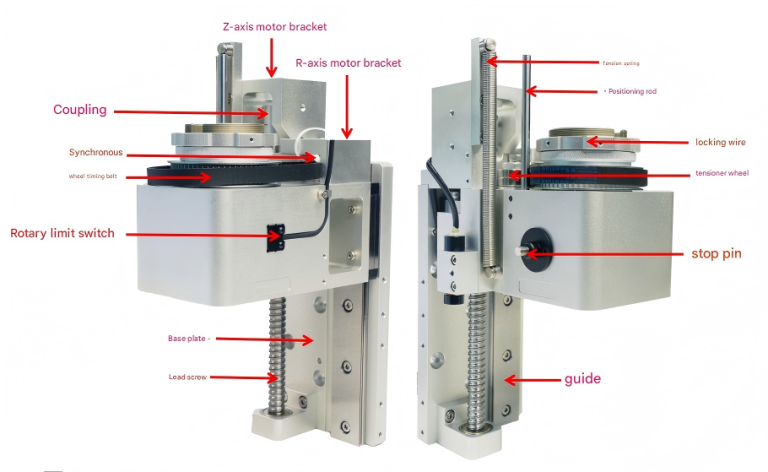

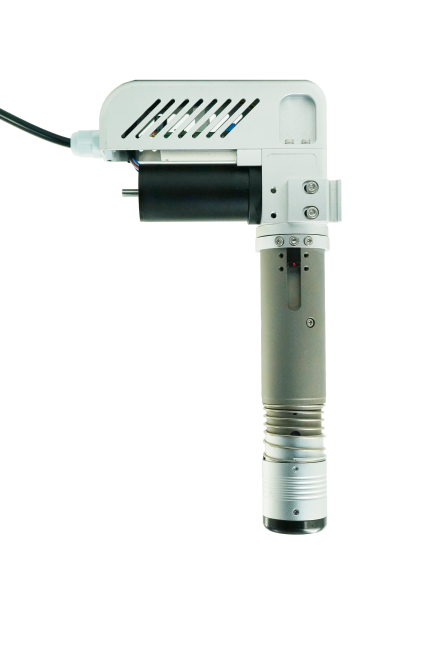

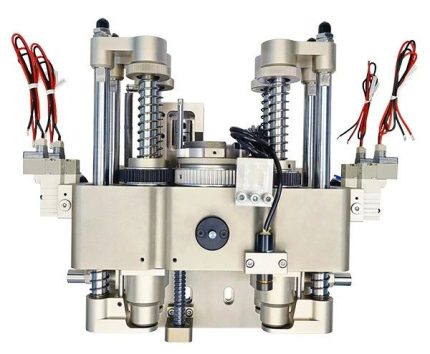

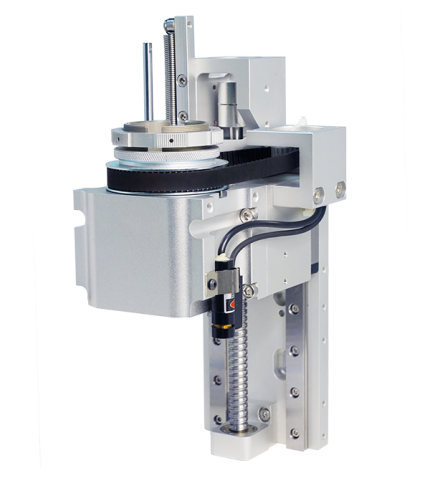

Tool holder 80 can be equipped with vibrating knives, circular knives, pneumatic knives, drag knives, bevel cutters, milling cutters, pressure wheels, half cutters, table collectors, etc. Tool holder 80 adopts a lengthened and widened single guide rail and precision screw drive to realize Z-axis lifting, and a synchronous belt drive to realize tool rotation.

Component Description

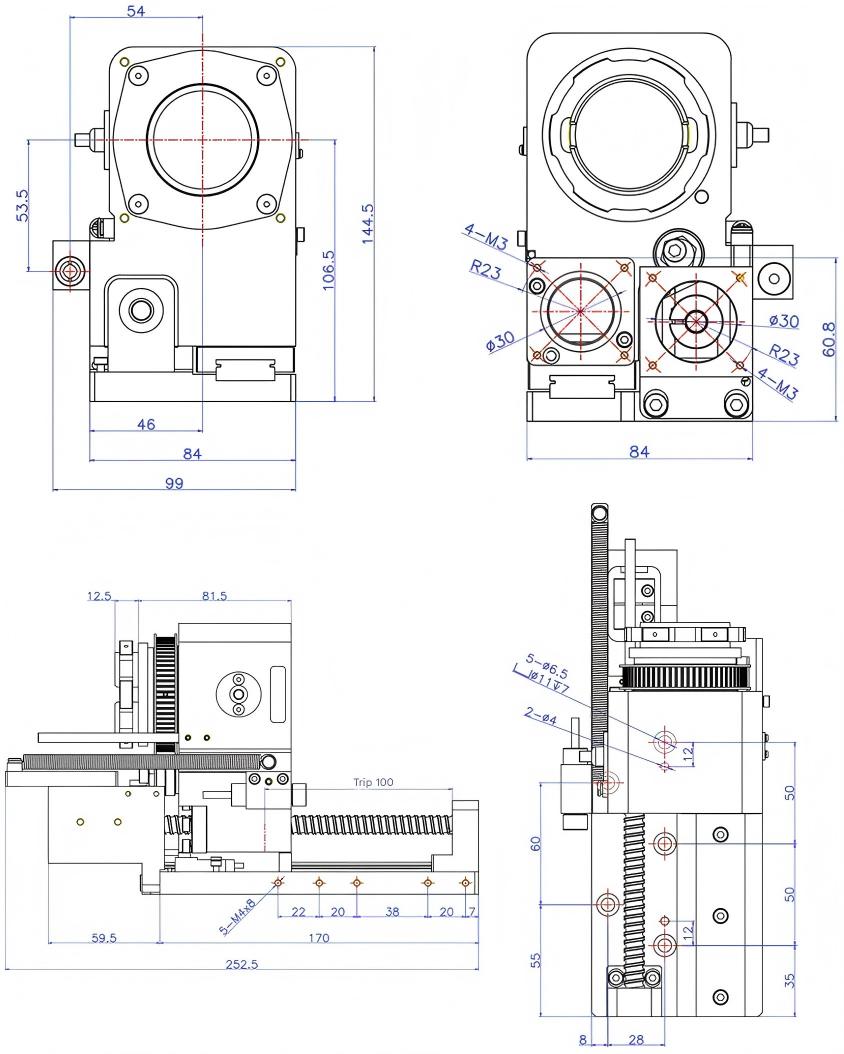

Installation Dimensions

Installation Diagram

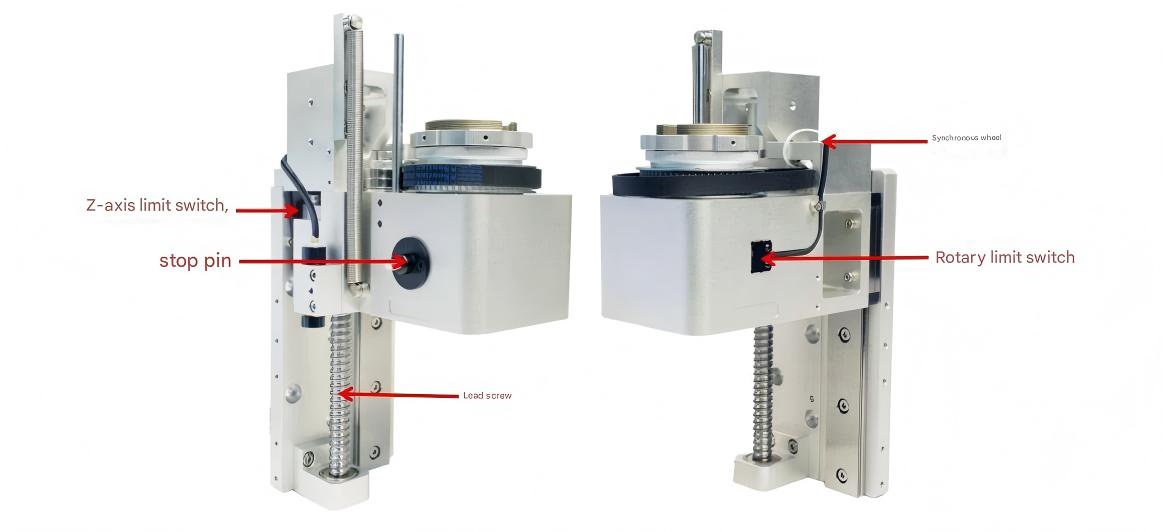

Instructions for use and debugging

Output: default output NPN NO

Stop pin operation: press the stop pin and rotate the knife barrel (synchronous wheel) until the stop pin is inserted into the hole;at this time, the stop pin is stuck in the knife barrel, and the locking screw can be loosened by hand or wrench

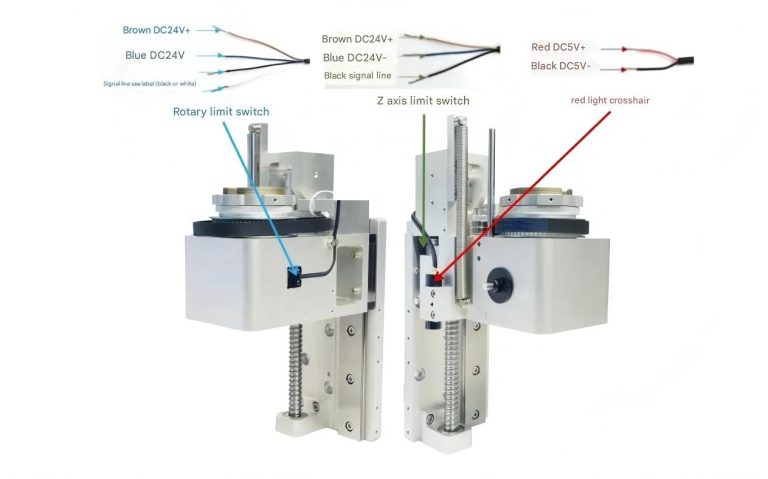

Wiring Instructions

| Red light crosshair | Red:DC5V+ Black:DC5V- |

| Z-axis limit switch | brown:DC24V+ blue:DC24V- black:Signal line |

| R-axis limit switch | brown:DC24V+ blue:DC24V- Signal line see label (black or white) |

Precautions

1. Before powering on, make sure the wiring is correct

2.Use shielded cables to avoid interference

3. Confirm the tightness of the coupling

4. The red light on the knife holder defaults toDC5V power supply, and the limit switchdefaults to DC24V power supply

Product Parameters

| Order Model | Perce91135 |

| Number of tools that can be installed | 1 |

| journey | 97/207 |

| Dimensions | W99/H252.5/D144.5 |

| Weight | 2.5/2.8 |

Shipping Configuration

Tool holder 80

Optional accessories

Knife seat pressure plate

Heightened knife seat pressure plate

Servo Motor

Optional spare parts

Couplings

Small synchronous wheel of knife seat

Knife holder belt

Rotary limit switch

Z-axis limit switch

Red light indicator

Reviews

There are no reviews yet.