Overview

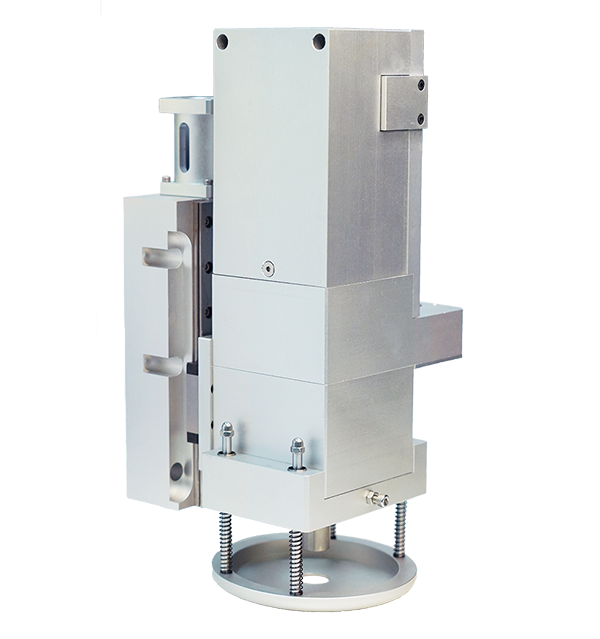

Servo-driven vibration knife can process advertising KT board, foam board, ABS plastic, corrugated plastic board, corrugated paper, cardboard, gray cardboard, wire ring mat, carpet, seal ring, carbon fiber prepreg and other materials.

The basic principle of vibration knife is to drive the blade to reciprocate at ultra-high speed through the motor to cut the material, which is particularly suitable for cutting and shaping medium-density materials. Different blades can be matched to realize the processing of different materials.

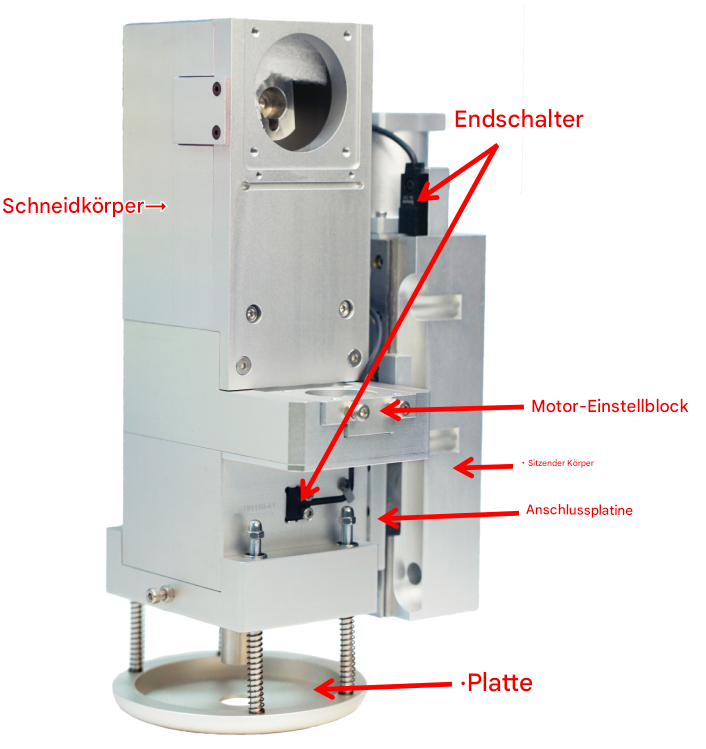

Component Description

Component Description

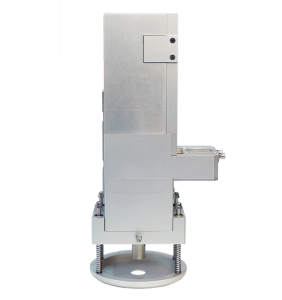

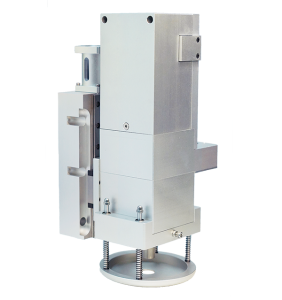

Cutter body: Vibrating knife body

Motor adjustment block: used to adjust the tightness of the synchronous belt

Pressure plate: used to press the material during cutting

Limit switch: limit the limit position of the stroke

Base: fix the servo vibrating knife on the machine tool

Connecting plate: connect the knife body and the base

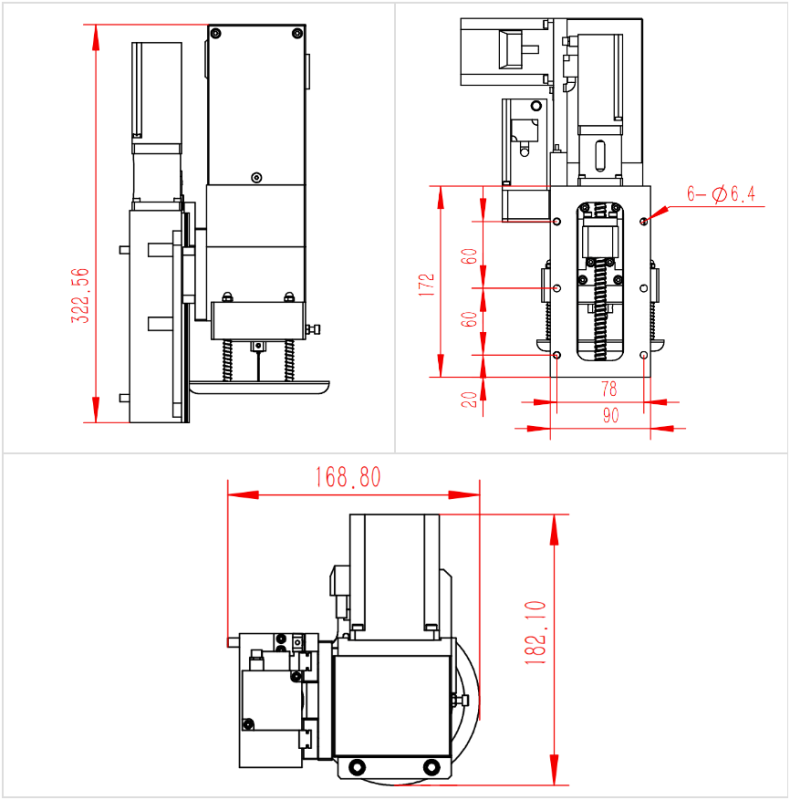

Installation Dimensions

Installation Dimensions

Instructions for use and debugging

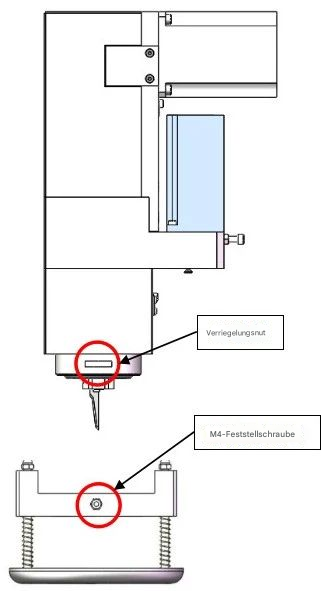

Installation of the pressure plate

Align the M4 locking screw of the pressure plate with the locking groove of the cutter body; insert the pressure plate upward into the cutter body and tighten the M4 screw; check whether the connection between the pressure plate and the cutter body is tight. If so, the installation of the pressure plate is complete.

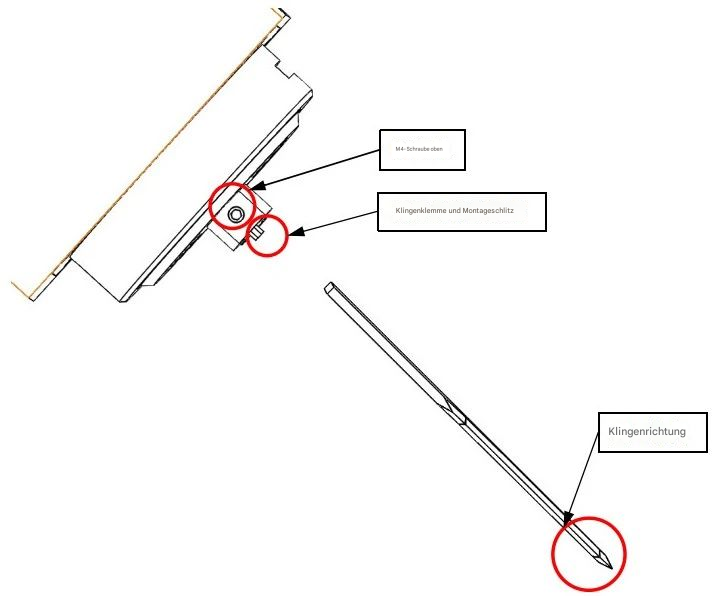

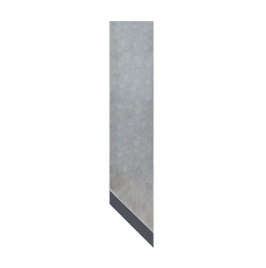

Blade installation

The blade edge faces the top screw; insert the blade into the installation slot. When the blade is pressed against the top screw, it is installed in place. Tighten the M4 top screw; check whether the blade is firm. If so, the blade installation is complete.

Blade clamp removal

Method 1: Use a screwdriver to move the blade clamp back and forth. Once the blade clamp is loose, you can remove it (recommended).

Method 2: First clamp the waste blade with the blade clamp, then clamp the blade clamp with pliers and pull it out.

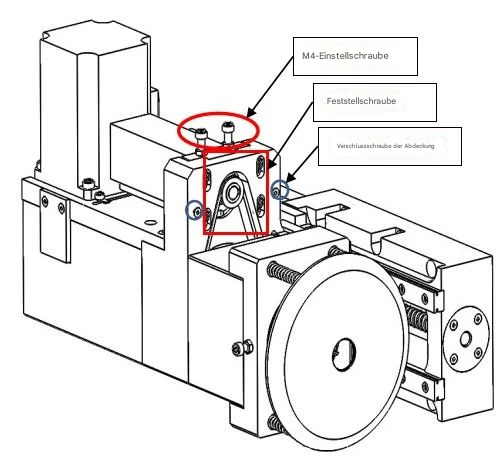

Adjustment of synchronous belt tension

Loosen the two cover locking screws and remove the cover;

Slightly loosen the four locking screws until the motor adjustment block can slide;

Twist the two M4 adjustment screws. At this time, check the tension of the synchronous belt while turning the screws. The synchronous belt can be slightly tightened;

Finally, tighten the four locking screws to fix the motor housing, and tighten the two cover locking screws to fix the cover.

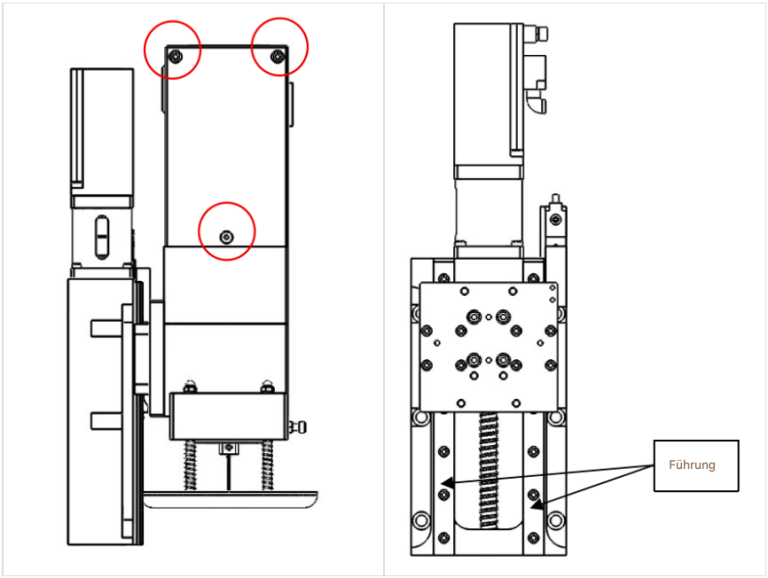

Oiling and maintenance

Loosen the three fixing screws to remove the cover and inject lubricating oil into the internal mandrel to lubricate the mandrel; lubricating oil can be applied to the guide rail frequently to maintain its durability.

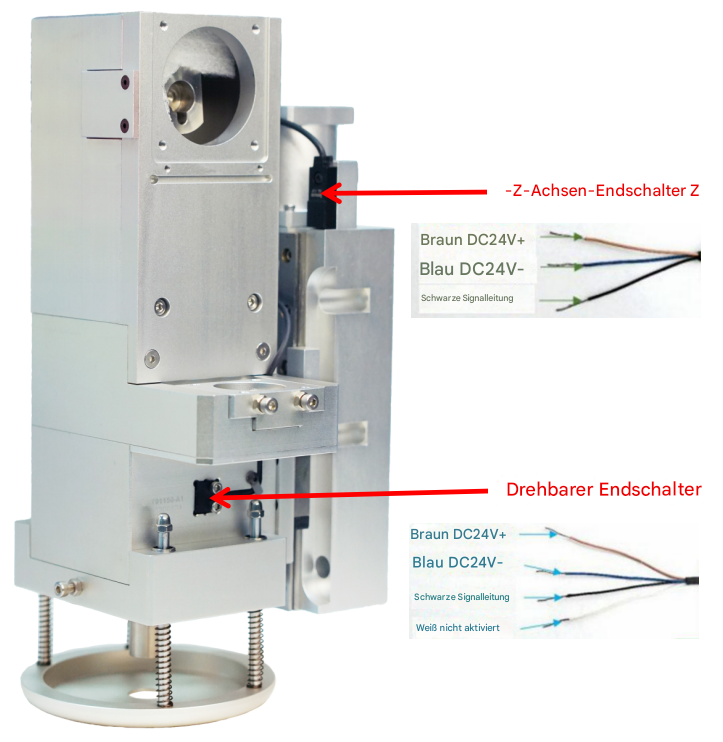

Wiring Instructions

| Rotary limit switch | Brown:DC24V+ Blue:DC24V- Black:Signal line |

| Z-axis limit switch | Brown:DC24V+ Blue:DC24V- Black:Signal line |

Precautions

1. Before powering on, make sure the wiring is correct

2. Non-professionals are not allowed to disassemble the blade

5. Install the blade in time and pay attention to safety

Product Parameters

| Order Model | Perce 91150 |

| Motor speed RPM | 0-5000 |

| Amplitude mm | 5/10/15 |

| Motor power/W | 400W |

| overall dimensions/mm | W381/H325/D161 |

| weight | 4.2 |

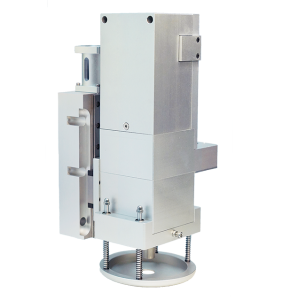

Multi-faceted appearance

Shipping Configuration

Perce 91150 Servo Driven Oscillating Knife

Perce 95010 Blade Clip

Perce 95014 Single Edge Blade

Optional accessories

Perce 95001 Pressure Plat

-3-272x300.png)

Perce 95010 Blade Clip (0.63/1/1.5/2mm)

Perce 95011 Blade Cap

-1.png)

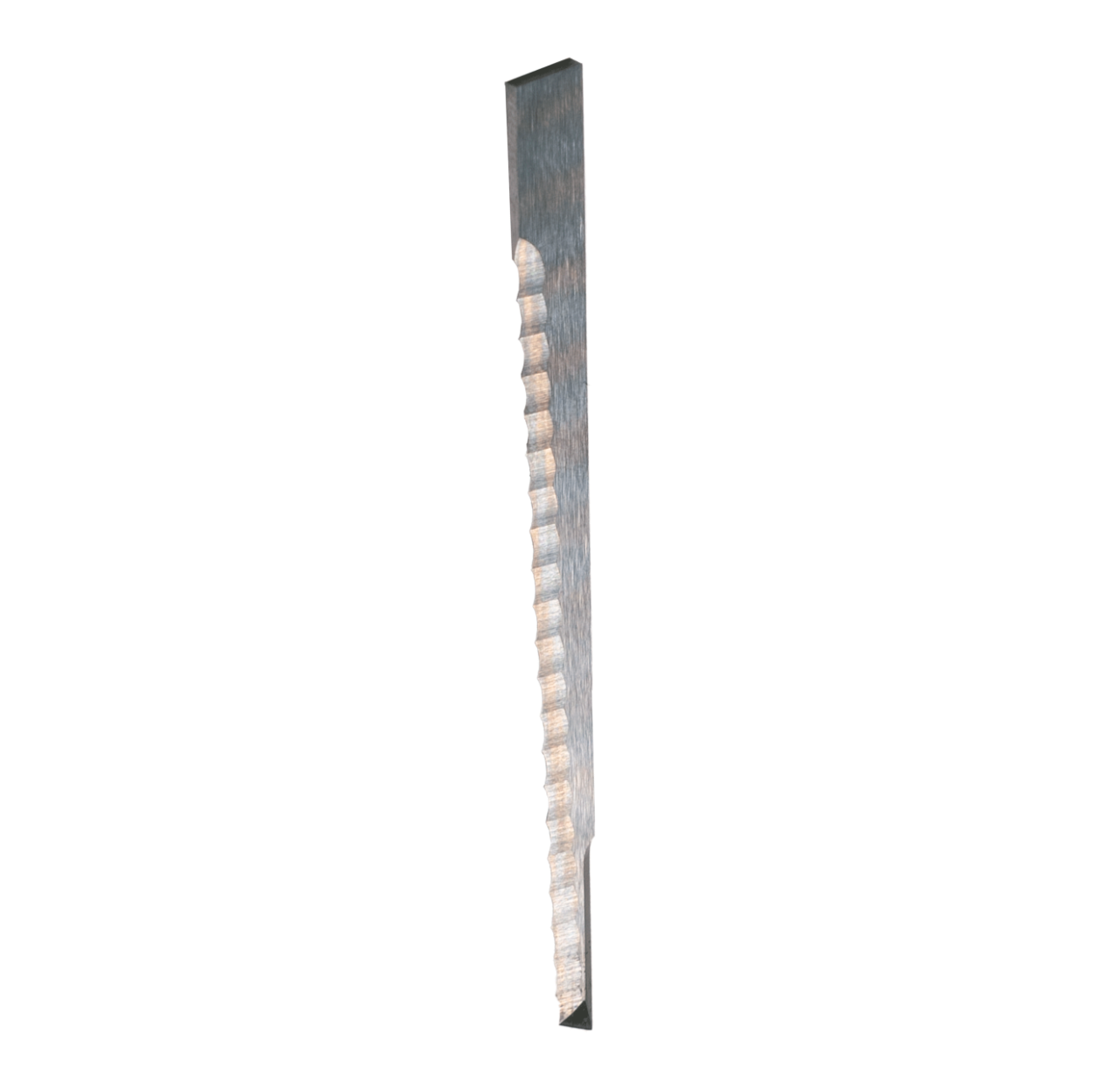

Perce 95014 Single Edge Blade

-1.png)

Perce 95015 Double Edge Blades (Various Sizes)

Perce 95034 Serrated Blade

组合刀头带振动刀)-430x573.png)

Reviews

There are no reviews yet.