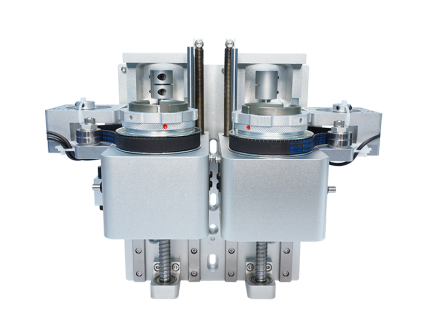

Product appearance and overview

The pressure cutter can process materials such as stickers, car stickers, reflective stickers, magnetic stickers, PP paper, PP adhesive, rubber cloth, imitation leather, cardboard, soft glass, etc.

The pressure cutter can achieve material cutting through the rapid movement of the tool. It allows cutting materials at the fastest processing speed, with high cost performance and low maintenance cost.

With blades of different angles, the best cutting effect of different materials can be achieved.

Component Description

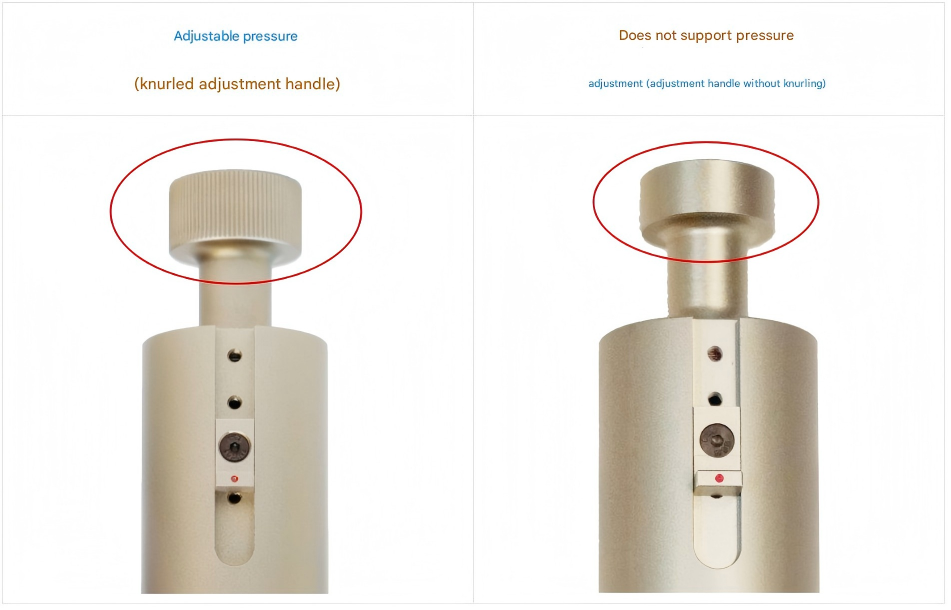

Adjustment handle: adjusts pressure.

Lock: used to lock the knife handle.

Knife handle: presses the blade.

Locking screw: fixes the adjustment ring.

Adjustment ring: fine-tunes the blade depth.

Locking screw: fixes the press barrel.

Press barrel: presses the material.

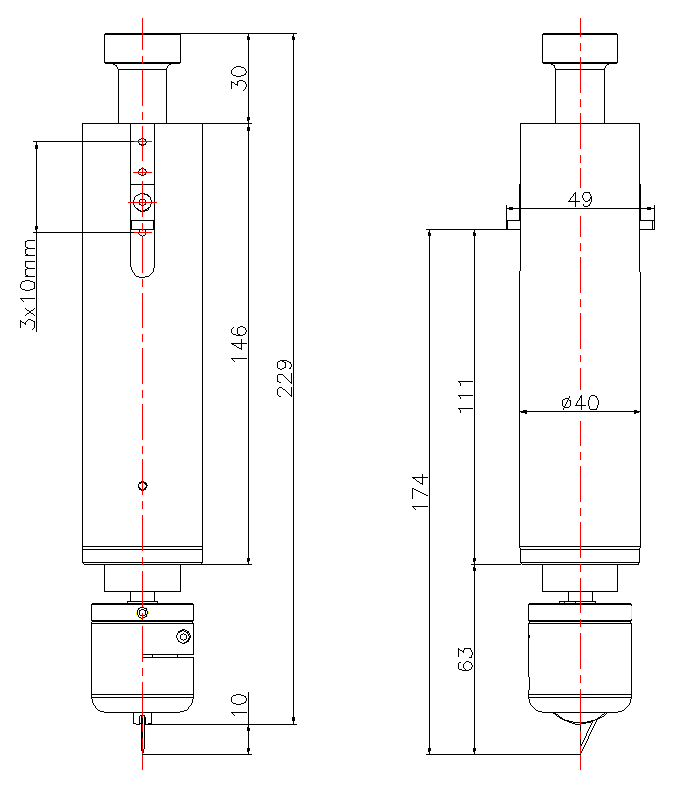

Installation Dimensions

Installation Diagram

Instructions for use and debugging

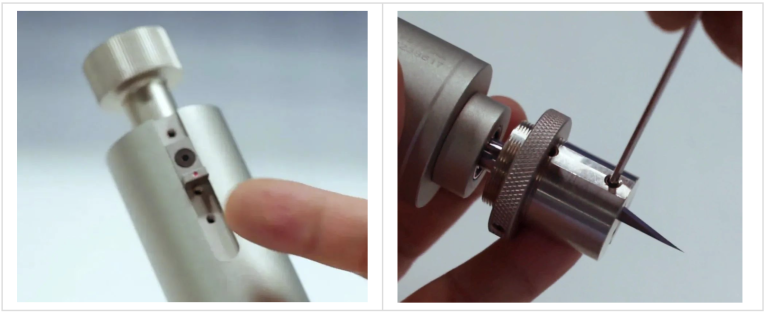

1. Blade installation

Use a wrench to unscrew the locking screw and remove the press barrel.

Align the blade with the red dot and tighten the top screw.

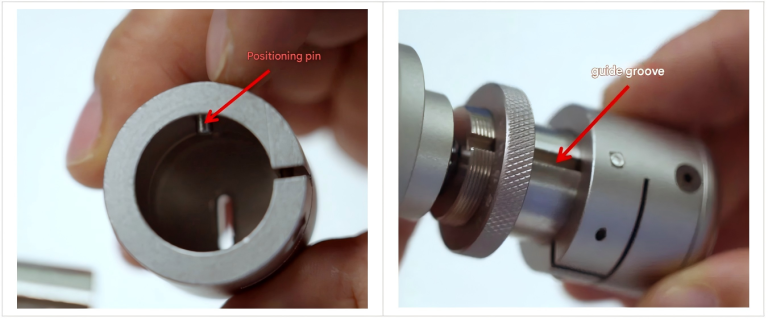

Align the positioning pin with the guide groove and install the pressing barrel.

2.Adjust the knife depth

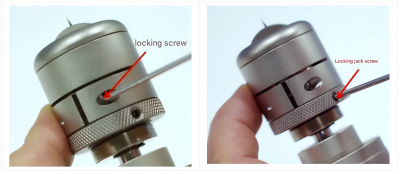

Slightly loosen the locking screw of the press barrel to maintain a little resistance; slightly loosen the locking screw of the adjustment ring to maintain a little resistance.

Rotate the adjusting ring to expose the knife tip to a suitable length, and then tighten the locking screw and locking top screw to complete the knife depth adjustment.

3.Pressure adjustment

Turn the adjustment handle to adjust the pressure.

Precautions

Non-professionals are not allowed to disassemble the cutter head.

Order Model

Product Parameters

| Order Model | Perce91176 |

| Cutting thickness/mm | 6 |

| Overall dimensions/mm | W49*H229*D40 |

| Weight | 0.4 |

Optional parts and accessories

Press Cutter

Single edge blade

Reviews

There are no reviews yet.