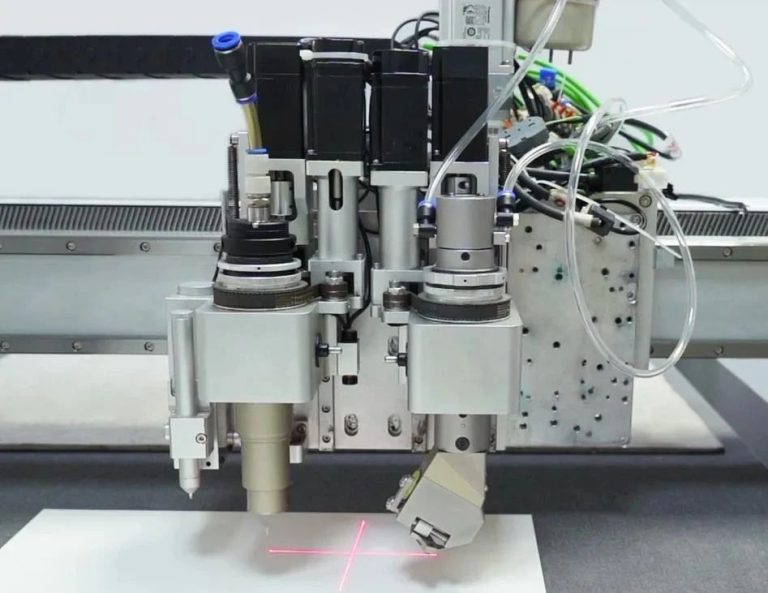

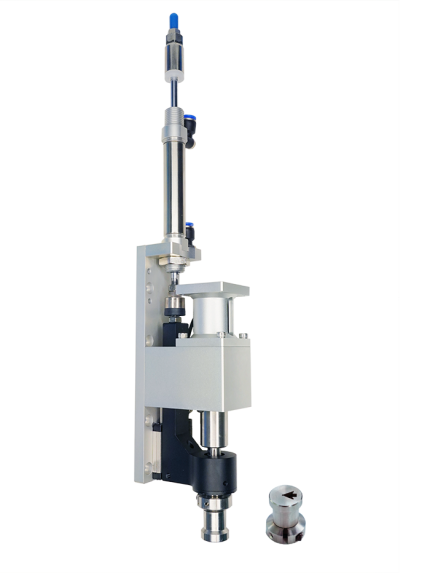

Product appearance and overview

The basic principle of pneumatic bevel cutter is to drive the blade to cut V grooves through compressed gas. It can process soft glass, PVC, honeycomb board, KT board, vertical corrugated paper, gray cardboard and other materials.

Component Description

Air pipe connector: connects the air pipe, air inlet.

Fixed block: fixes the blade.

Lock: used to lock the blade handle.

Brace: pneumatic bevel blade.

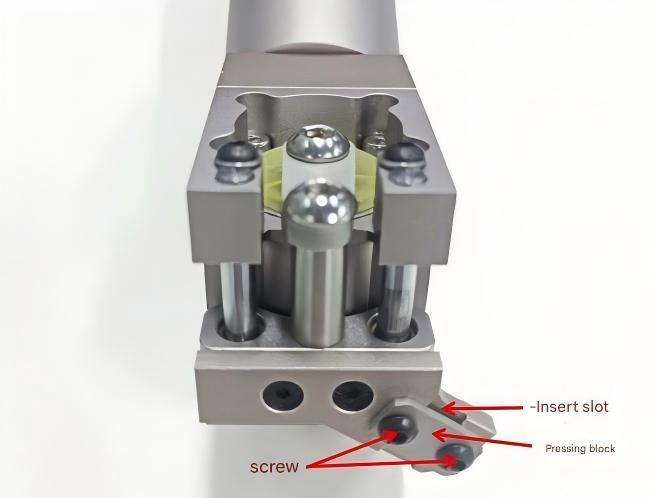

Countersunk screw: used to fix the blade.

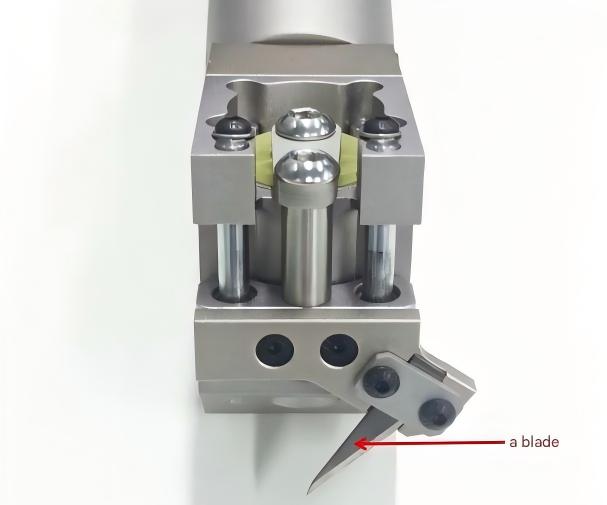

Tool holder: install the blade.

Pressing block: the tool holder part, clamps the blade.

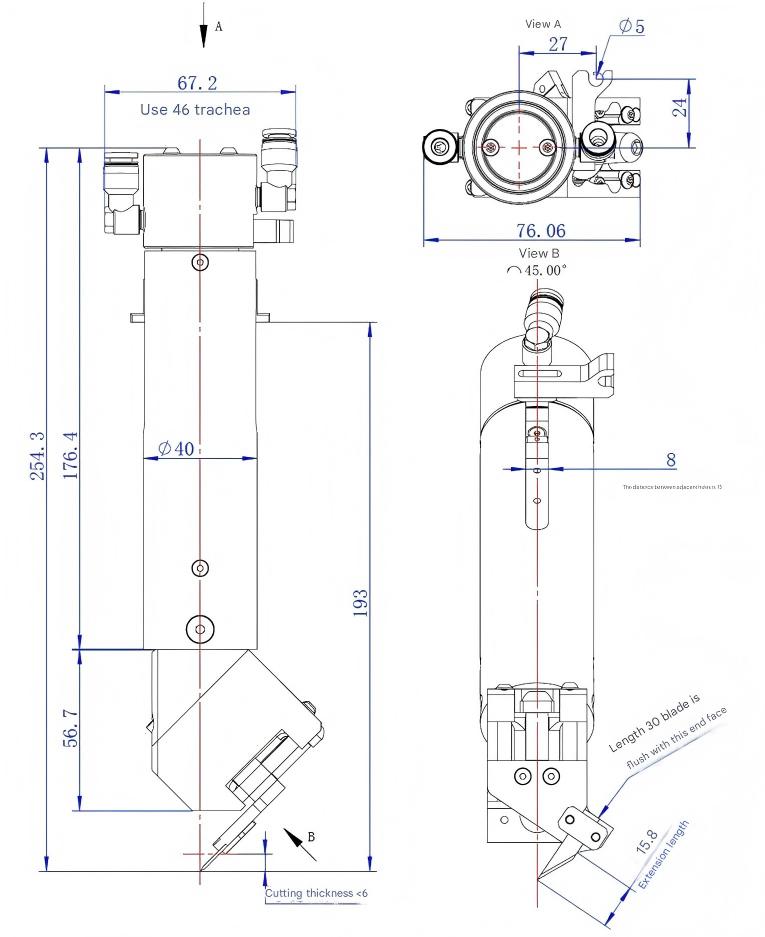

Installation Dimensions

Installation Diagram

Instructions for use and debugging

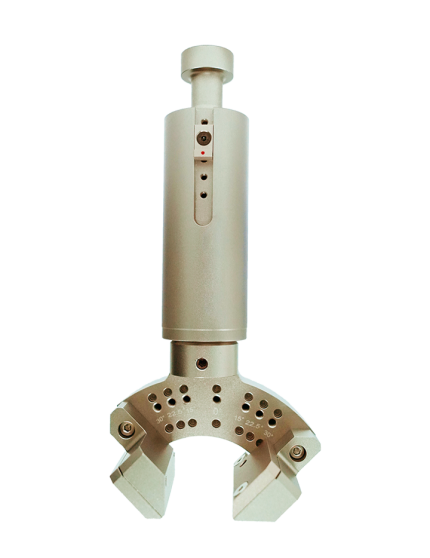

Installation and removal of blades

-Blade installation

Loosen the two screws, loosen the blade block, align the blade and put it into the blade slot in parallel. The blade extension length is 15.8mm. Pay attention to the direction of the blade when installing.

After installing the blade, tighten the screws. When tightening, pay attention to the gap between the blades. If the gap is too large, the blade will easily fall out. (The M4 screw can be loosened to adjust the height of the blade).

-Blade Removal

Loosen the two screws and the blade will come loose and can be easily removed.

Precautions

1. Non-professionals are not allowed to disassemble the cutter head.

2. Clean and dry compressed gas must be connected. (For example, a pneumatic triplex is used to filter, reduce pressure and add oil to the gas to ensure the normal operation of the pneumatic actuator and prevent malfunctions due to impurities, excessive air pressure or lack of oil.)

Order Model

Product Parameters

| Order Model | Perce 91278 |

| Working air pressure | 0.6MPa |

| Cutting thickness/mm | 5mm |

| Overall dimensions/mm | W67.2/H254.3/D76.02 |

| Weight | 0.8 |

Shipping Configuration

Pneumatic bevel cutter

Optional accessories

Single Edge Blade

Reviews

There are no reviews yet.